Electrifying Last Mile Deliveries Can Create a More Sustainable Supply Chain

When package delivery is powered by electricity, even non-drivers can benefit from EVs.

Spend any time in a city and you’ll see it: an idling box truck, blocking bike lanes as its driver unloads packages, one by one. This common sight is more than a minor inconvenience; it’s a congestion-causing bottleneck that undermines the efficiency of urban living. And as consumer behaviors evolve and more packages are being delivered – with a record $5.54 trillion in global e-commerce sales projected in 2022, according to research firm Insider Intelligence – the problem is only getting worse.

The World Economic Forum forecasts that, without implementation of innovative solutions, this change in how we buy and receive goods will cause a huge strain on city infrastructure globally, with demand for urban last-mile delivery – getting a package from a warehouse to the customer – forecasted to grow by 78% by 2030.

Take the world’s 100 largest cities and add 36% more delivery vehicles to meet the insatiable e-commerce demand, and the scope of the problem becomes clear. Thankfully, the same electrification initiatives that are reimagining passenger vehicles are coming to the supply chain.

Primed for Disruption

Package delivery is the useful use case for electrification. Few drivers of passenger EVs have set needs or destinations. One day they may travel 20 miles; the weekend may be a 300-mile family road trip. But delivery vehicles generally follow fixed, predictable daily routes that are usually under 150 miles, and the trucks often return to a depot overnight, where they can be easily charged.

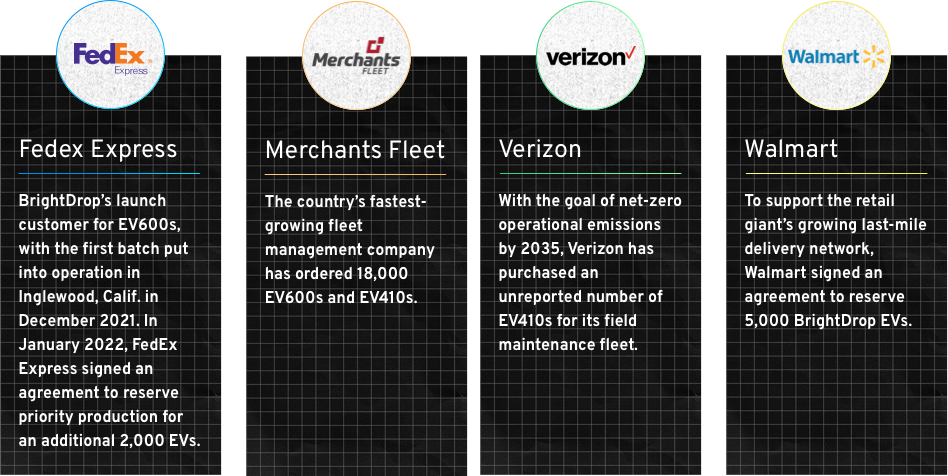

Recognizing this opportunity, General Motors announced the launch of BrightDrop in January 2021. A tech startup bolstered by GM’s 113-year legacy, BrightDrop aims to decarbonize last-mile deliveries by offering a holistic ecosystem of all-electric first- and last-mile products and services. This makes the company a critical pillar of GM’s goal to provide zero-emission mobility access to all.

Put another way, even city dwellers who don’t own cars can benefit from the rise of EVs.

But the simplicity of this logic obscures the ambition of the BrightDrop project. “Our mission is to fundamentally reshape our cities through smarter and more efficient ways to deliver goods and services,” says Travis Katz, President and CEO of BrightDrop. “So we’ve created a connected ecosystem of products – electrified vehicles and containers with software and services packaged around them – designed to meet the challenges of the explosion in e-commerce.”

“It’s really about bringing together software with hardware to create an ecosystem designed around e-commerce.”

— Travis Katz, CEO and President of BrightDrop

A Growing Fleet

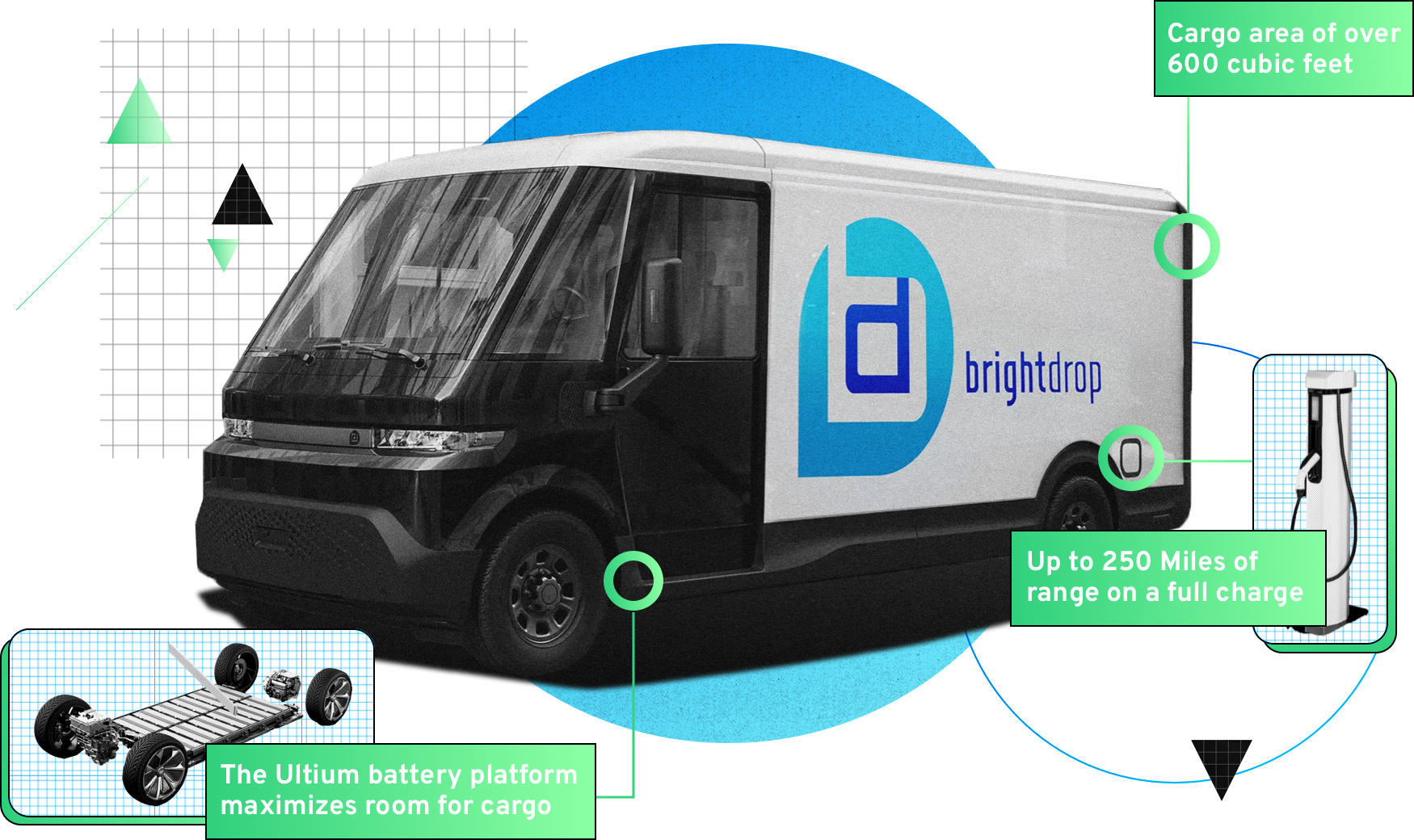

The hardware Katz references begins with a pair of light commercial EVs: the EV600, BrightDrop’s flagship long-range hauler, and its midsize fleetmate, the EV410. Both have an extended battery range (up to 250 miles on a full charge) and their interiors maximize cargo space– features made possible by GM’s modular, space-efficient Ultium battery platform.

BrightDrop’s biggest breakthrough is what Katz describes as “containerization of the last mile.” Just as the humble shipping container – simple 8' x 40' boxes that can be stacked onto cargo ships like building blocks – revolutionized global commerce, BrightDrop has a similar vision for last-mile delivery.

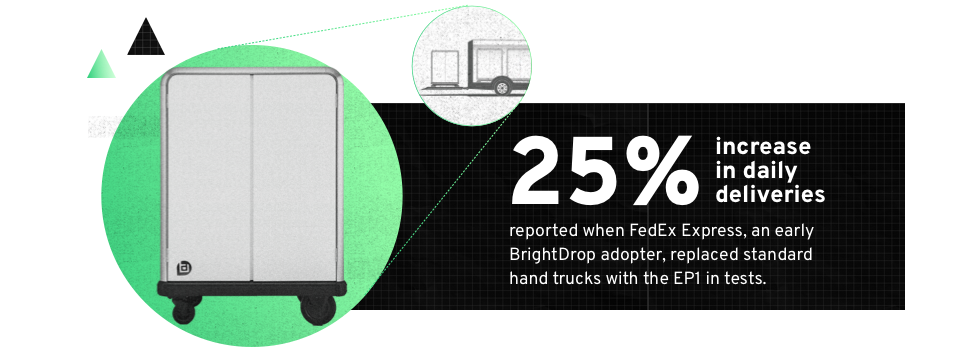

To help speed deliveries, maximize productivity and reduce physical strain on couriers, GM created the EP1, a wheeled container with a built-in electric motor. At the warehouse, for example, packages can be organized by route and loaded directly onto the EP1 – an upright container with a 200-pound capacity – with multiple EP1s loaded onto a delivery vehicle like the EV600. In the field, an EP1 and courier are dropped off at a destination (say, a Manhattan office building), while the delivery vehicle is free to head to its next stop.

FedEx Express reported couriers were able to effectively handle 25% more packages per day when it replaced standard hand trucks with the EP1, in a Toronto-based pilot. “This kind of efficiency can really change the game, allowing companies to scale without sacrificing the end consumer experience,” says Katz.

In a second limited pilot in New York City on routes in a high-density, vertical urban environment, the EP1 allowed couriers to increase package deliveries by 15% per hour and cut delivery curbside dwell time in half. FedEx plans to expand EP1 testing to 10 markets beginning in 2022.

Another of the world’s largest companies is enlisting BrightDrop to help meet its sustainability goals. At CES 2022, Walmart announced plans to reserve 5,000 EV600s and EV410s in a partnership that will help the retailer in reaching its goal to operate a zero-emissions logistics fleet by 2040.

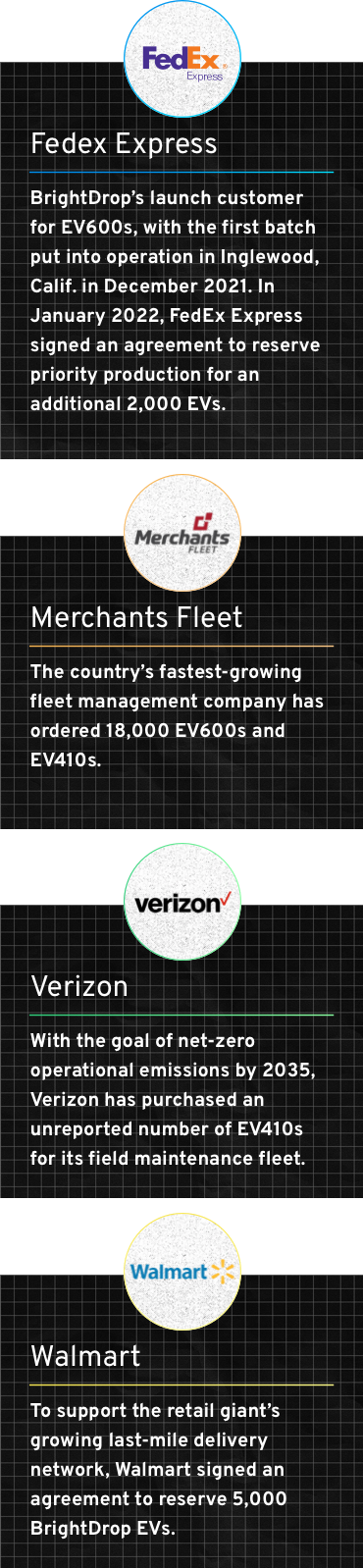

Who’s Using BrightDrop?

These commercial customers are already electrifying their supply chains

An Ecosystem of Insights

BrightDrop’s EVs and EP1s double as IoT-connected devices, forming the foundation of a fleet management platform that provides access to real-time logistics and chain of custody data.

With sensors streaming information onto BrightDrop’s cloud-based software platform, companies are provided broad visibility into the supply chain, from real-time package location to vehicle battery performance and tire pressure. This data provides continuous insights into how to optimize hardware to reduce per-mile costs.

If a customer notices that a particular road intersection adds minutes a day to operations, for example, they can identify a more efficient route. “You really allow companies to do more with fewer vehicles on the road, which could mean less congestion and less emissions,” says Katz.

Startup Agility with Legacy Scale

BrightDrop, a wholly owned subsidiary of GM, marries the agility and focus of a technology startup with the tremendous scale and manufacturing ability of a major automaker.

“In tech, you need to experiment – to move very fast and fail very fast,” Katz explains. “BrightDrop gets to run at the speed of a startup, but with all the might that GM brings – not just batteries for EVs, but the manufacturing and supply-chain knowhow.”

Case in point: When conceiving the EV600, BrightDrop leveraged both the physical flexibility of the Ultium Platform and the virtual development processes that GM established when designing the GMC HUMMER EV. With that head start, against global supply chain headwinds brought on by the pandemic, the EV600 went from concept to production in only 20 months – the fastest in GM’s history.

“We get the best of both worlds with this combination of a fast-moving technology startup backed by a strong automotive incumbent that knows how to build and scale.”

— Travis Katz, CEO and President of BrightDrop