Dreamers Who Do

Collaborative clean-tech innovation finds a fast-emerging home in the UAE

The United Arab Emirates is a country whose people have repeatedly proven their ability to turn vision into reality.

From its transformation from a small pearl-diving community into a trade, finance, and tourism hub, to the strides in business, technology, education, and diplomacy at home and across the globe, the country and the people who call it home have become synonymous with the phrase,” “Dreamers Who Do."

The country’s earliest dreamers were its forefathers, whose resilience, optimism, and spirit of innovation ensured they could survive in a harsh desert environment.

Today, its dreamers are carrying forward this legacy of innovation—working to make the planet healthier, cleaner, and more sustainable. Food Security. Biofuel. Clean Water. Sustainable Building. Solar Power. Bioplastic. Trapping Pollutants. Carbon Capture. Rethinking Transportation. Space Technology. AgriTech. Replenishing Groundwater. Precision Medicine. Encouraging Lifelong Learning. Emiratis and residents—representatives of the more than 200 nationalities that call the UAE home—are working on all these topics and more as they help make the country, the region, and the world a better place.

Here are some of their stories.

Dr. Nicolas Calvet, Assistant Professor in the Mechanical Engineering Department at Khalifa University of Science and Technology and founder and chair of the Masdar Institute Solar Platform, which is dedicated to concentrated solar power and thermal energy storage.

The Contributor

Nicolas Calvet grew up in Perpignan, in the sunny south of France. That may be where his love of all things solar comes from: the town is located near the mountainous border with Spain, about eight miles from the Mediterranean Sea. He’s spent his career working on how to store sunlight—and is pioneering using waste material to do it.

The Technology

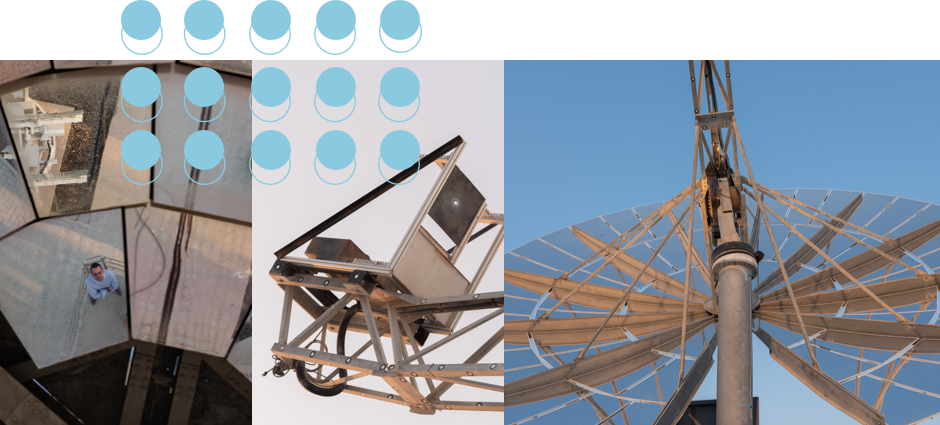

Solar energy is available only when the sun is shining, making energy storage crucial for 24/7 deployment.

Unlike photovoltaics (PV), which generate a charge directly from the sun’s power, concentrated solar power plants (CSP) – or solar thermal—use mirrors to concentrate light and create heat that is used to turn water into steam to drive a turbine. The heat is usually stored in molten salt to be used later after sunset.

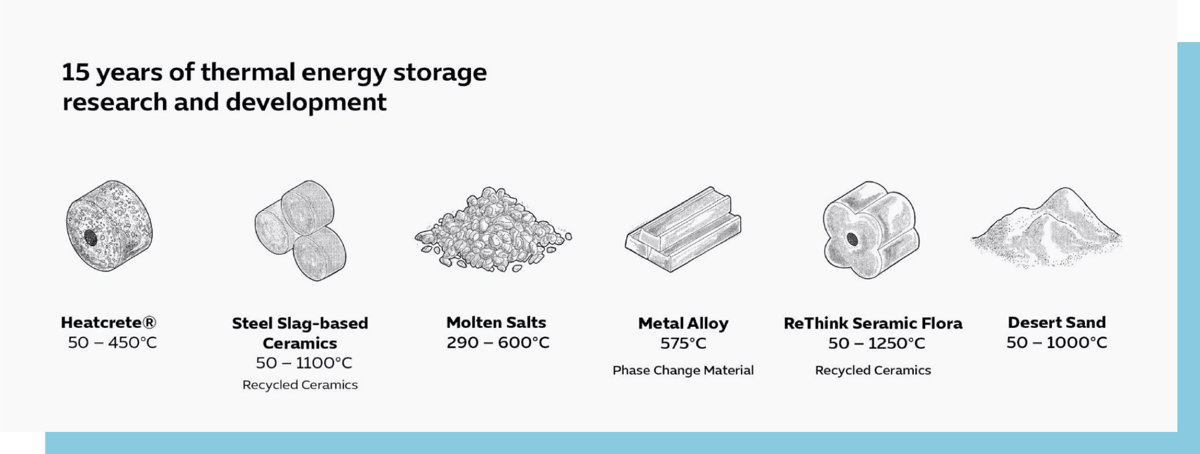

The higher the temperature this energy storage material can handle—and the lower the cost—the more efficient the conversion from heat to electricity.

And what could be cheaper than waste?

Calvet has made it his mission to seek out industrial solid waste that can be recycled as low-cost energy-storage material—in other words, replacing the salt. He began with asbestos-containing waste during his studies to tackle French stockpiles of the hazardous waste, and converted it into ceramic, a material that provides high-heat transfer surfaces and large thermal capacities.

In the UAE, he turned his attention to steel. Emirates Steel, the country’s biggest producer of steel and building materials, generates more than 800,000 tons of steel slag annually. This waste product has been converted by Calvet into ceramic (patent pending). Calvet has also set up his own company, Seramic Materials Ltd., which has developed ceramic using another waste type.

These ceramics can store heat at temperatures up to 1,250 degrees Celsius. That’s double the capability of salt, and less than half the price of non-recycled ceramic.

They can also work outside the solar industry, storing thermal energy from electricity in renewable energy systems such as solar photovoltaic (PV), wind, or excess grid.

So what’s next for this pioneer of recycled-waste ceramics?

Seramic already has two clients. One is Storenergy, a Serbian company that’s testing the material in Plataforma Solar de Almería—the largest solar test center in Europe and one of the world’s top three solar-test centers.

The other is Heliogen, which has billionaire backing from the likes of Bill Gates and Patrick Soon-Shiong. Heliogen seeks to use solar power to replace fossil fuel in heavy industries – cement, glass, ceramic, steel, aluminum, which account for almost 20 percent of global CO2 emissions today, according to the International Energy Agency—because concentrated solar plants can reach the high temperatures required. The company is currently testing Seramic’s product in its demonstration plant in California.

The UAE Startup Scene

The startup scene is emerging in the UAE, a country where funds are available and where there’s the political push to deploy innovative technology and renewable energy.

The country has committed to increasing the contribution of clean energy to 50 percent of its total energy mix by 2050; most of the clean energy will come from solar power. It’s home to the world’s biggest single-site solar plant and is securing the lowest tariffs in the market. Meanwhile Masdar, the UAE’s clean energy developer and investor, is funding renewable energy all over the world.

“The UAE’s solar resources are among the best in the world, so it’s really the place to be to experiment with solar technologies,” Calvet says. “The beauty of it all is that everything is financed by oil and gas, so it’s a good example of diversification of the economy.”

Monica Menendez, Professor of Civil and Urban Engineering, Director of the Research Center for Interacting Urban Networks (CITIES), NYU Abu Dhabi.

The Contributor

Monica Menendez was born and raised in Cuba. She has lived in Venezuela, US, Switzerland, and now the UAE. During her travels she has seen the different ways in which cities tackle mobility and has acquired knowledge that she brings to her research in reimagining transportation systems.

The Innovation

The need for transformation in mobility is intensifying as more people move to cities. Cities cannot continue to be car-centric—there’s simply no room. Meanwhile, traditional public transport is becoming unsuitable because of the fixed nature of bus and train systems.

Thinking about the transportation of goods is just as important, especially in a place like UAE, where most goods are imported and need to be transported across long distances.

Current mobility systems also consume a lot of energy. The UAE transport sector is responsible for about 60 percent of its total oil demand, according to the International Energy Agency.

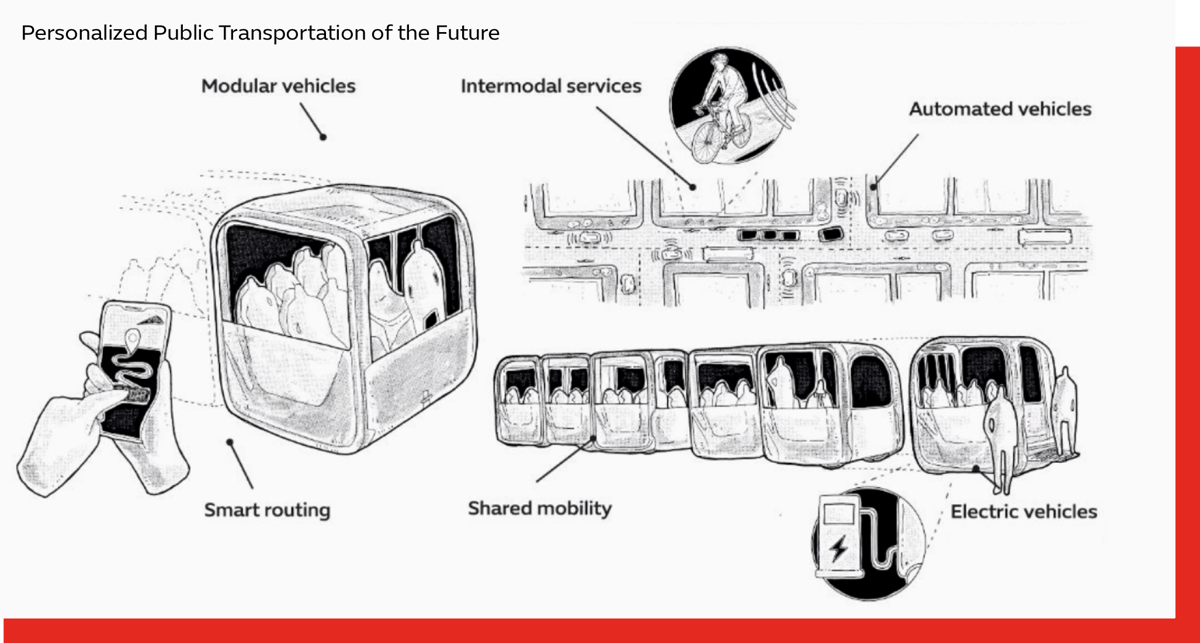

The solution, according to Menendez, is something between the traditional public transport service and a private car – or “inter-modality.” That means using multiple modes of transportation for any journey. That can include conventional transport, such as a bus, a car, a taxi, a bicycle or walking, or new technologies, such as an individual flight machine, autonomous cars, driverless vehicles, electric vehicles, on-demand services. Modular units—driverless vehicles that can join together as a single unit with a bigger capacity or be deployed individually—can even come together while on the move.

The goal is to produce efficient, sustainable, flexible transportation systems that deliver a customized experience, combined with a small spatial and environmental footprint.

“If you want to have a resilient economy, you need to have a good mobility service,” says Menendez. “This means we need to start relying on new technologies and information. Because the traditional ways alone, the improvements that we can get by improving our car a little bit, for example, are marginal.”

How do we make these new journeys possible?

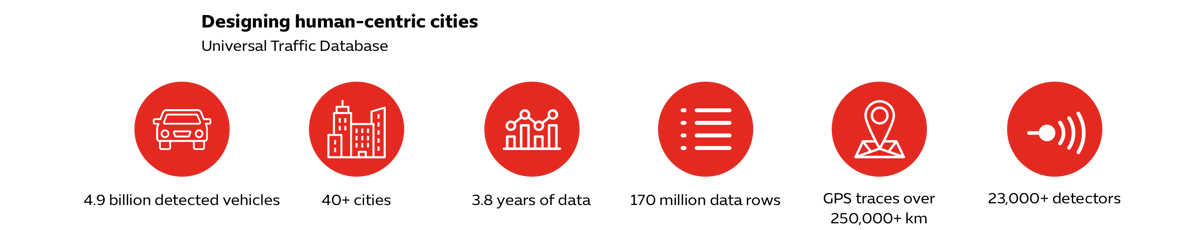

That is what Menendez is working on. She’s studying patterns discovered from monitoring traffic using 23,000-plus detectors in 40-plus cities over nearly four years that she claims is “the largest publicly available traffic data set that exists.” The data spans 170 million rows and includes detection of 4.9 billion vehicles and GPS traces over more than 250,000 kilometers.

Insights from the analysis of these data sets, coupled with her interest in emerging new technologies, can be used to inform policy-making and urban and transportation planning.

Inter-Modality in Action

Real-world impact will come as soon as some of Menendez’s algorithms are implemented. This could be in two or three years, or it could take 10 years, she says. It also depends on how much technology is involved. Simple changes to public transport systems could be made fairly quickly, but driverless cars or taxis at the city level will be a different story.

Transportation is a highly regulated environment, and there are many different stakeholders involving risk, technology, legislative, insurance and cybersecurity that need to come to the table to make big changes in transportation possible.

“In countries that are well established, it's like, ‘Well, we’ve been doing it this way for the last 100 years,’” says Menendez. ‘Do we really need to change it?’ The answer is yes, but it takes much more effort to convince them. Countries like the UAE are a blank canvas. There’s appetite for it. And there's also a need because cities in the Middle East are growing very fast.”

Dr. Shadi W. Hasan, Associate Professor, Department of Chemical Engineering, Khalifa University.

The Contributor

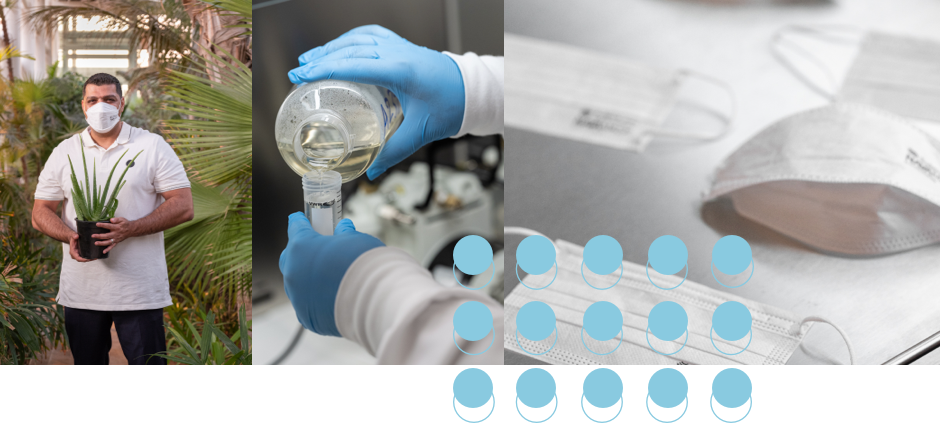

Shadi Hasan was born and raised in the emirate of Abu Dhabi. During the pandemic, he recognized the toxic waste that was growing exponentially as people in the world over donned face masks to prevent the spread of the COVID-19 virus. He realized he might have a solution: an environmentally friendly face mask, based on a filter he was developing to clean wastewater.

The Innovation

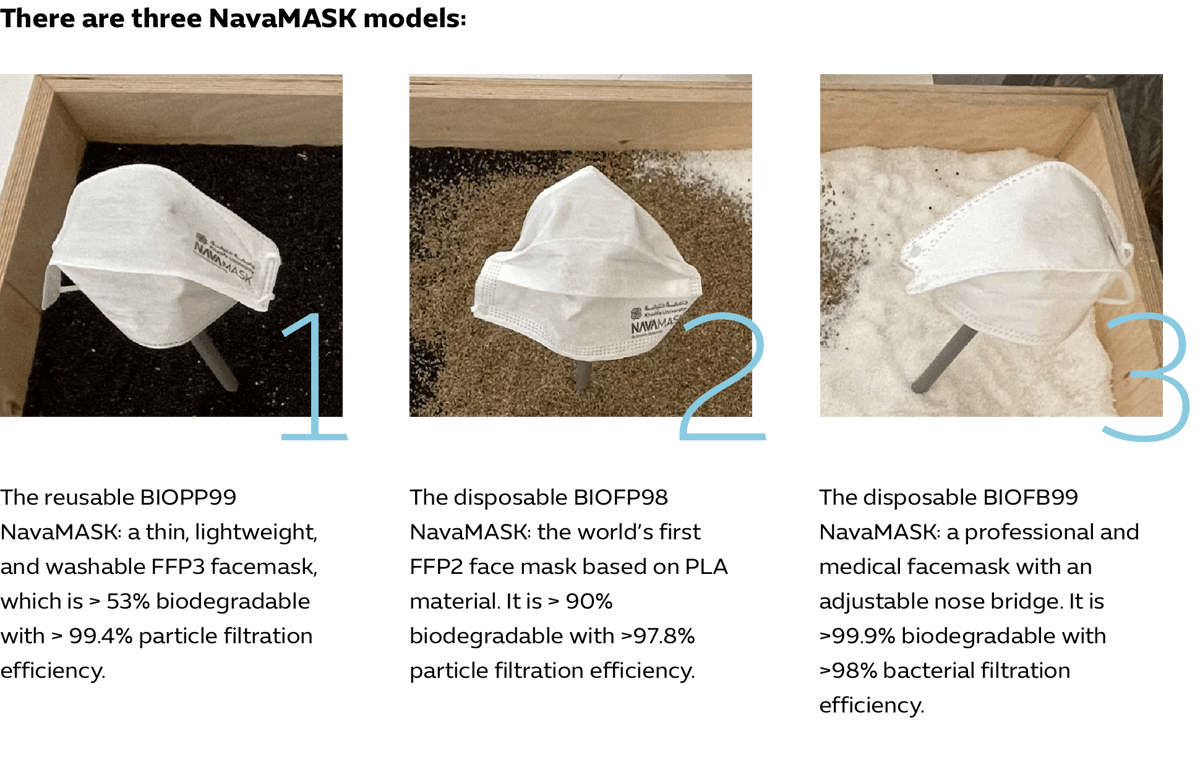

He called this innovation NavaMASK, a biodegradable, eco-friendly and sustainable facemask. These masks are made of polylactic acid, a biopolymer derived from renewable resources like corn starch and sugar cane.

The bioplastic is central to the face mask’s environmental friendliness, compared to the conventional plastic-based masks we use today. The world uses about 3 million masks a minute, according to research from the University of Southern Denmark published in 2021. That’s creating additional solid waste that needs to be treated and disposed of, and risks degrading into microplastics and nanoplastics, tiny particles that contaminate soil, air and especially the ocean, where they can be ingested by animals and fish and get stuck in their gut. NavaMASK, though, can be composted, recycled, and integrated back into our ecosystem. Several models of NavaMASK were developed and can be either a one-time use or washed and reused several times prior to eventual disposal.

To make it easier for people to breathe in the masks, Hasan and his team are deploying a technology called electrospinning to produce nanofibers from the bio-based polylactic acid. Electrospinning, a filtering technology used in desalination, will be the next-generation technology to produce face masks, according to Hasan.

“Think of a mask as a filter, which has pores,” says Hasan “The larger the pores, the more breathable the mask is. The challenge is how to achieve very high removal of bacteria and maintain high breathability. Nanofibers are very, very thin lines scattered perpendicular, vertical, horizontal. You don't see them. But while the pore size is very small, the overall surface area for breathability is really large. This is where we can achieve both at the same time: high protection, and high breathability.”

These nanofibers are coated with antimicrobial medicinal plants to reject bacteria and provide high efficiency, from Aloe Vera to common household spices such as black seeds, anise, turmeric and coconut.

Patents and Production

Hasan has filed a U.S. patent application for this multifunctional filtration material – the biodegradable concept can be used for applications other than masks – and the team is now at the stage of commercializing NavaMASK. Exposure at the UAE Pavilion during Expo2020 has attracted investors from around the world who see it as a golden opportunity, not only from an environmental perspective, but also as a business, says Hasan. And it goes well with the UAE’s efforts and vision, as the country prepares to host COP28, the 2023 UN Climate Change Conference.

The production line is the same as for existing masks. Hasan is currently discussions with an industrial mask supplier to establish a production line in the UAE as a hub for NavaMASK. Once the investment and a site are confirmed, production could begin in a matter of months.

Mask prices are expected to increase again as the COVID-19 crisis recedes and low-cost, uncertified, non-medical mask manufacturers shut down. NavaMASK prices are currently on par with the cost of a mask before the pandemic, but the company is working to cut prices to make them competitive even at current price levels.

“If you have the choice between an environmentally friendly and a non-environmental-friendly mask for the same price, which one are you going to go for? This is our ultimate objective,” says Hasan.

The UAE Pavilion is the host country pavilion at Expo 2020 Dubai which tells the story of the "Land of Dreamers Who Do"; from its ancient roots as a crossroad for people, goods and ideas, to its transformation into a unified nation and a home to people from over 200 countries. Learn more at UAEPavilionExpo.com