Industry 5.0: Transforming the Manufacturing Paradigm

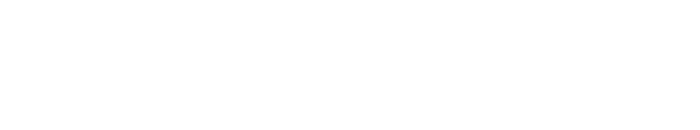

Manufacturing has long been recognized as one of the most challenging sectors to decarbonize. With its heavy resource intensity and high greenhouse gas emissions, it accounts for almost one-third of energy consumption and energy-related carbon emissions globally, according to the United Nations Industrial Development Organization.

Yet a significant shift is underway. As the rapid development and adoption of artificial intelligence (AI) transforms businesses, and corporate demand for sustainability, supply chain resilience and transformation capital grows, a new era of advanced manufacturing is emerging, according to Amit Midha, CEO of Alat, a new global enterprise in Saudi Arabia that aims to transform manufacturing.

“Today’s supply chain dynamics demand a fundamental shift in thinking,” Midha says. “Geopolitical complexities, economic uncertainties and environmental imperatives are pushing us beyond traditional efficiency-focused models toward true resilience. I believe this evolution is critical.”

In partnership with powerhouse companies like Softbank and Lenovo, Alat is at the forefront of this revolution. With plans to bridge the global transition funding gap with an investment of $100 billion over the next five years, Alat is developing a sustainable manufacturing hub that will lead the transformation of advanced manufacturing.

Powered using clean energy, the Riyadh-based hub is focused on nine key industries including semi-conductors, smart devices, smart buildings, smart appliances, smart health, advanced industrials, next gen infrastructure, electrification and AI infrastructure. With a focus on research and development into new technologies and energy efficiency, Alat is partnering with some of the world’s leading innovators and universities to reimagine multiple industrial manufacturing processes from the ground up.

As with previous industrial revolutions, technological innovation is the foundation of this next generation of manufacturing. Advanced AI, robotics and automation systems are pivotal to the future processes of the Fifth Industrial Revolution (“Industry 5.0”).

While the focus of Alat’s world-class sustainable manufacturing hub is to harness this technology to transform global electronics and advanced industrials and deliver sustainable manufacturing solutions, the benefits of sustainable advanced manufacturing don’t stop at technological advancements, improved processes and lower carbon emissions. The progress is vital to future-proof manufacturing businesses by delivering greater production efficiencies, reducing financial, regulatory and climate risks—and improving bottom lines.

Generative AI algorithms, for example, can predict and manage equipment maintenance, reducing downtime and energy use. And manufacturing connectivity through the Internet of Things can help manufacturers achieve new efficiencies in their use of materials, labor and energy.

Crucially, the integration of IoT and AI into supply chains allows manufacturers to monitor and automatically adjust energy consumption in real time, which is critical to achieve sustainability goals. Today’s consumers and regulators expect companies to disclose their carbon footprints, and manufacturers that are proactive in reducing emissions have a competitive edge as they build trust with environmentally conscious stakeholders and position themselves favorably in global markets.

Calling the need to transition a “moral and business imperative,” Midha says the integration of AI and automation is creating a more efficient industrial paradigm in which sustainability is no longer a choice, but a given. “As carbon accounting becomes stricter, advanced manufacturers face an ultimatum to adopt sustainable practices or face potential financial and operational risks,” he says.

AI-driven energy and process efficiencies will be vital to meet net-zero targets, but manufacturers must also harness green materials and increase their use of clean energy to reduce carbon emissions and protect their financial performance. This will require a significant injection of capital, with a mix of electrification, renewable energy and efficiency improvements necessary to meet these goals.

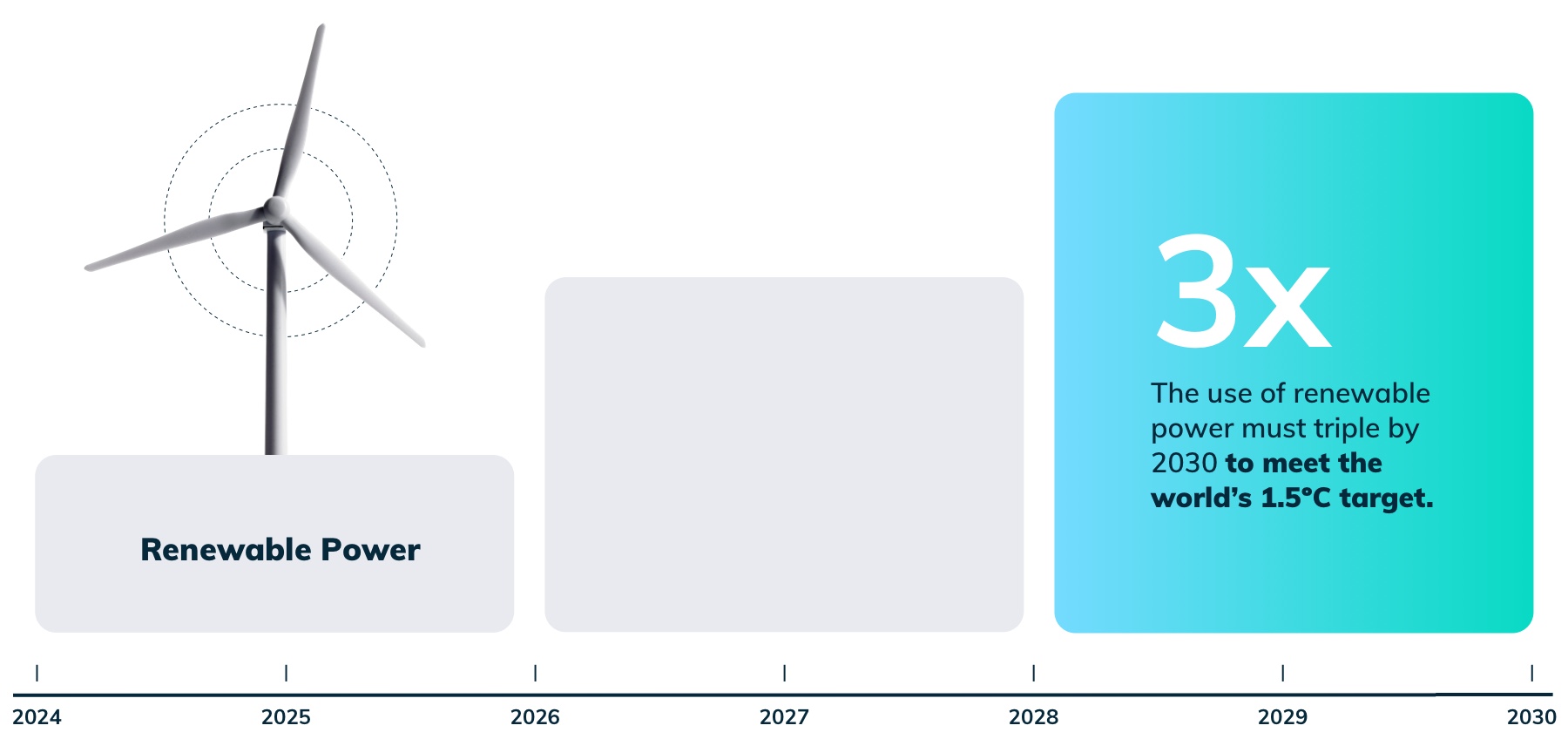

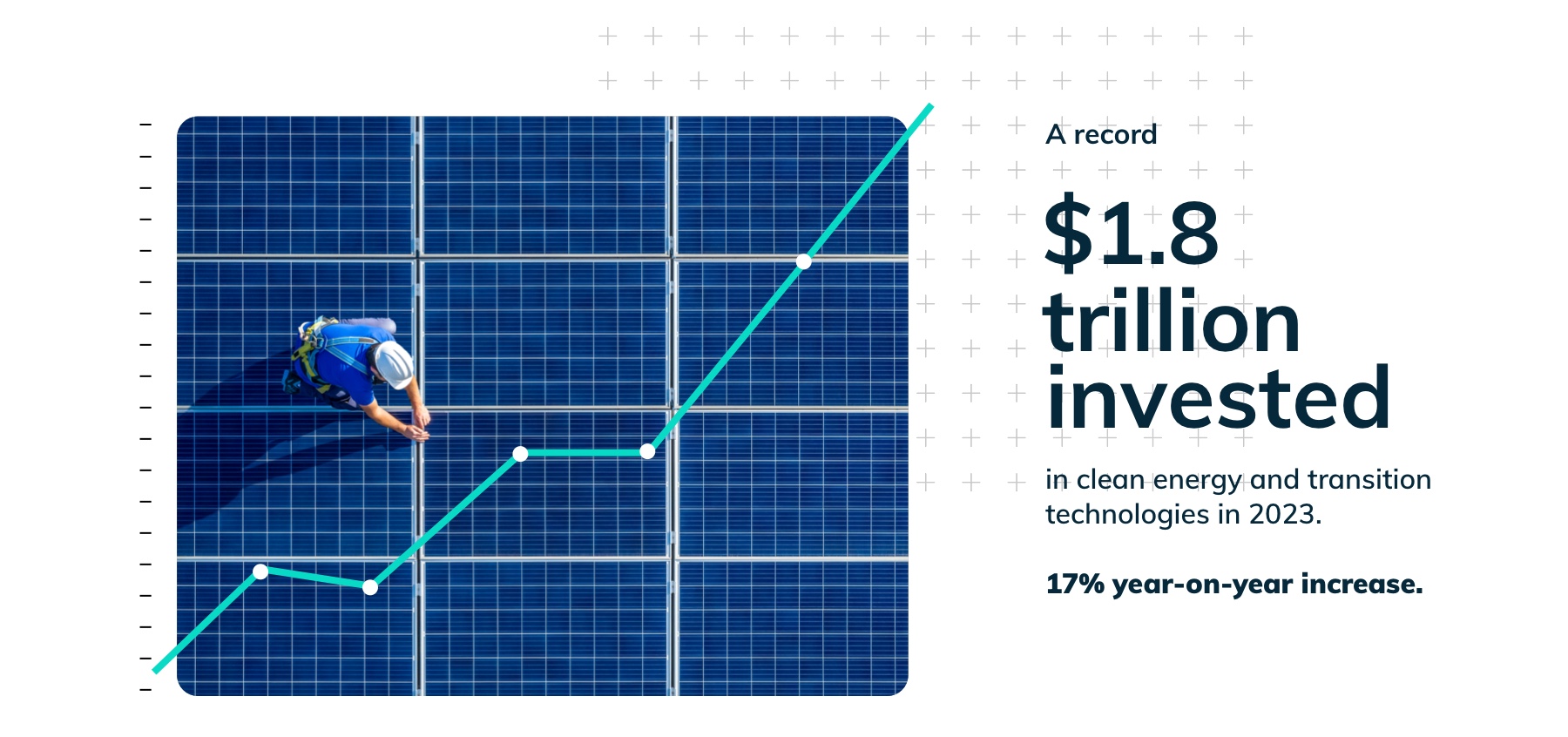

According to the International Renewable Energy Agency, the use of renewable power must triple by 2030 to meet the world’s 1.5°C target, while energy efficiency improvements must double. Although global investment in energy transition technologies has soared—a record $1.8 trillion was invested into clean energy and transition technologies in 2023, a 17% year-on-year increase—the sustained investment needed to achieve these targets is far beyond any private-sector commitment.

Midha says partnerships will be instrumental to bridge this gap as they help provide the funding and innovative thinking needed to create a robust and sustainable manufacturing ecosystem that aligns with international energy transition needs. For this reason, partnerships are foundational to Alat’s strategy.

“Alat builds partnerships to ensure that the transformation of the industrial sector can happen on a global scale. These partnerships catalyze innovation, reduce risk, improve competitiveness, foster market expansion and enable shared access to resources,” he says. “Ultimately they drive the entire industry toward a more sustainable trajectory and enhance innovation.”

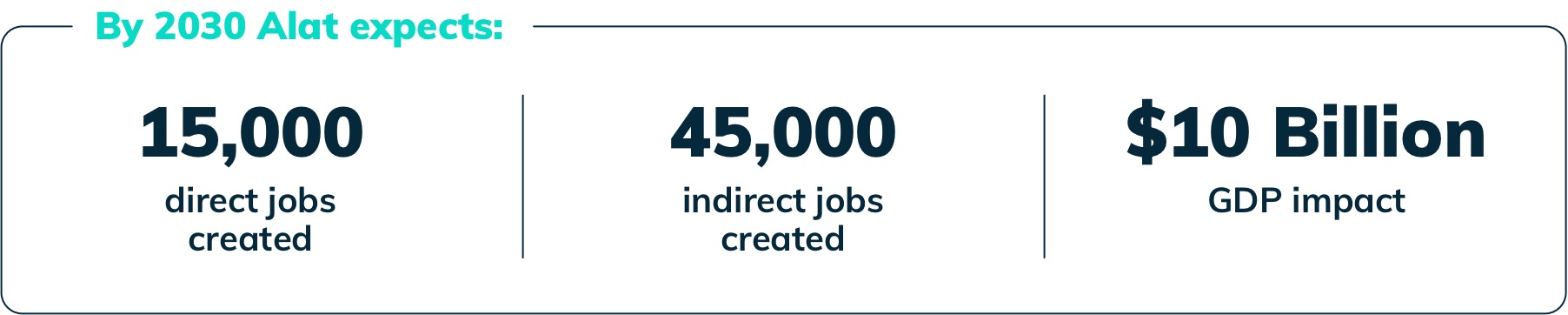

Alat’s most recent partnership is a US$2 billion investment and strategic collaboration deal with global technology giant Lenovo. Completed in January 2025, the partnership will see Lenovo establish a new Middle East and Africa regional headquarters and sustainable manufacturing hub in Riyadh to capitalize on the growth opportunities in Saudi Arabia and beyond. Alat expects the partnership to create 15,000 direct and 45,000 indirect jobs locally and to generate a cumulative GDP impact of $10 billion, in line with Saudi Arabia’s Vision 2030 goals.

“Alat has partnered with companies from around the globe from day one. The company uses a rigorous, data driven and strategy led approach to identify and integrate with partners, and deeply engages with partner companies at the C-suite and board level to ensure there is alignment and a commitment by both parties to fulfil our ambitious mission,” says Midha.

“For Alat, the goal is not just technology innovation, but also creating resilient supply chains and supporting international businesses in their sustainable transitions through these strategic alliances.”

As AI, automation and clean energy drive down costs and build resilience, and investors increasingly back low-carbon initiatives, the manufacturing sector is on the tipping point of a significant transformation.

Advanced technologies and innovation are key to achieving this transformation. However, incremental change will not be enough, according to Dr. Stefan Hoetzl, President of the Smart Appliances business unit at Alat. He says that a fundamental reshaping of manufacturing is needed to reach net zero, and that this requires ongoing dedication from industry leaders and policy makers, and the innovation and funding that Alat can provide.

As sustainability moves to the forefront of corporate strategy, the manufacturing industry’s capacity to adapt could very well determine its future profitability and resilience in an era increasingly defined by climate accountability. Alat’s out-of-the-box thinking will be critical in building this sustainability and resilience, and its innovation hub could place Saudi Arabia on the map as a global manufacturing powerhouse.