Shining a Light on Provenance: How Supply Chain Data Can Revolutionize Your Sustainability

Avery Dennison is a Business Reporter client.

Climate change is the defining issue of our era and will dominate the next few decades as the world desperately seeks ways to stave off the worst effects of global warming.

Businesses will be pivotal to this effort as significant contributors of emissions, and are at the heart of any attempt to increase traceability. Put simply, this is the ability of brands and manufacturers—and their retail customers—to demonstrate exactly where individual components of items have come from, and that they have been sourced or made in an environmentally and socially responsible fashion.

Global materials science company Avery Dennison is helping to create a system that will allow firms to do just that through the launch of its digital venture, atma.io. “We have this fundamental belief that in the future every physical item will have a unique digital identity,” explains Max Winograd, VP, atma.io and connected products, at Avery Dennison Smartrac. “Over the past several years, we’ve built our business around being a force for good and enabling connected products through a portfolio of intelligent labels. atma.io is really the next step in that digital transformation journey, managing all of that product data.”

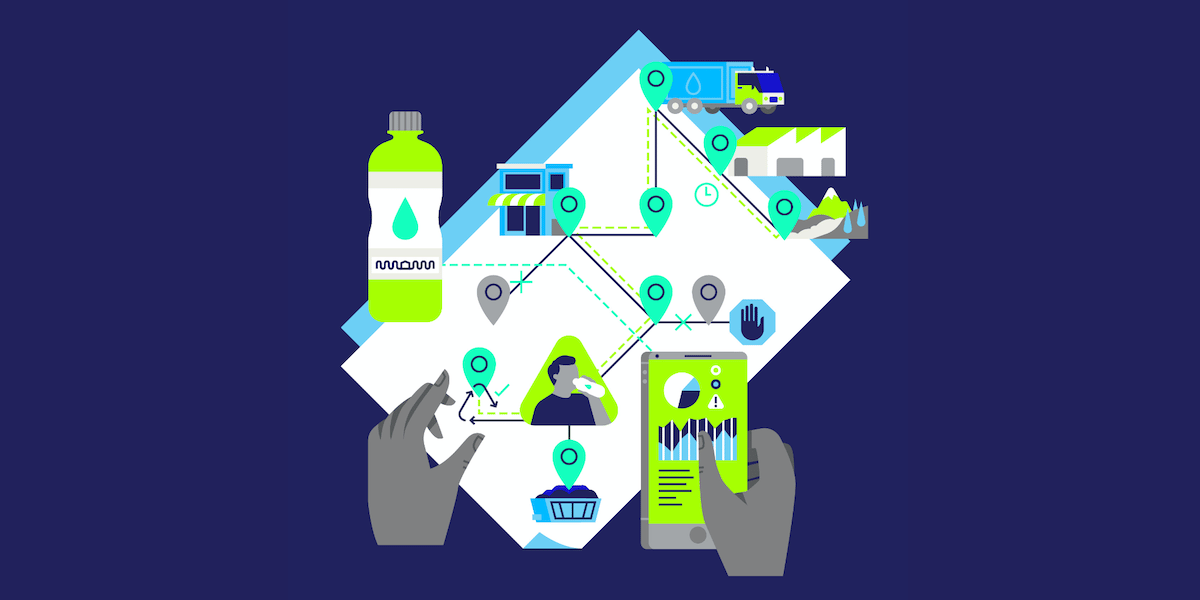

Winograd uses the example of a “snowball of data,” gathering more material as it progresses through its life journey. “We give each item a unique digital identity, which serves as the first snowflake,” he says. “Every time that digital identity is interacted with, data gets associated with it. At every step of the supply chain, from raw materials through to the purchase, and then every time consumers interact with it, as well, it’s collecting information. It’s another touchpoint to inform the consumer, but it also helps brands understand how consumers are interacting with products and, ultimately, how they can make more sustainable decisions around how they design products and enable circularity at the end of a product’s life.”

This data is stored in a connected product cloud, he explains, with more than 16 billion physical items already on the platform and 300 new ones being added every second. The business is already working with six of the world’s top 20 apparel brands by revenue, and four of the top 10 quick-service restaurants.

The reasons prompting businesses to get on top of the provenance of their products are varied, says Winograd. “The main ones that we see emerge as consistent themes are that brands want to have a more personalized experience with their consumers,” he says. “They want to be able to connect with the consumer post-purchase in new and unique ways, and to build more loyalty and trust with them. Another reason is around sustainability, where brands want to have a better understanding of what their impact is on the world, and how they might be able to reduce waste and carbon emissions.

“A third motivation is to then use that item-level information to get a more granular view of what’s happening in their supply chain—for instance, identifying where there might be bottlenecks or cases where certain products from certain factories are driving higher recalls or returns,” he adds. “That helps consumers have an added layer of confidence in the brands they buy products from and allows the brands to minimize waste and management costs.”

Different sets of data are being combined to deliver additional insight to brands. “We’ve taken this partnership to five of our largest customers, and they’re activating the first wave of pilots to see how these datasets together can create added value for them,” says Winograd. “That’s around better visibility going down their supply chain into the factories that supply products to them, while also being able to turn this into a story that they can tell their consumers, who want to know more about accountability, transparency and visibility into how they’re operating their supply chains. This is giving them the tools to actually convey that information to all their stakeholders, whether they’re regulatory bodies, suppliers, retail customers, consumers or their own employees.”

Accuracy of information is at the heart of the concept, and atma.io includes features designed to identify any potential issues on this front. This includes flagging any potential anomalies such as products being scanned in unexpected locations, and the use of distributed ledger technologies to provide additional transparency and encryption around the data that is being added to digital footprints.

The message for brands is to take action, believes Winograd. “As soon as you put these digital triggers onto a product and assign it a unique digital ID, you can start understanding and collecting data about how efficient your supply chain is from a sustainability and carbon footprint perspective, at an item level,” he says. “From there, you can start to measure and monitor, and to take action to reduce waste and your overall environmental impact. It’s about thinking where you want to be in five years’ time and taking that leap to start the process that will get you there.”

—Industry view from Avery Dennison

To find out more about how atma.io can help you take action on sustainability, visit atma.io.

This article originally appeared on Business Reporter.

Image credits: Header: Shutterstock 1094326709, Body: Courtesy of Avery Dennison