From Hype to Hands-On: How a Lean AI Strategy Delivers Results

Every company has an AI story. Few have real-world wins.

Three-quarters of C-suite executives report seeing no tangible returns from their AI investments, according to Boston Consulting Group. Business leaders are pulling back on initiatives that promised transformation but have delivered little beyond proof-of-concept pilots.

But some companies have broken through.

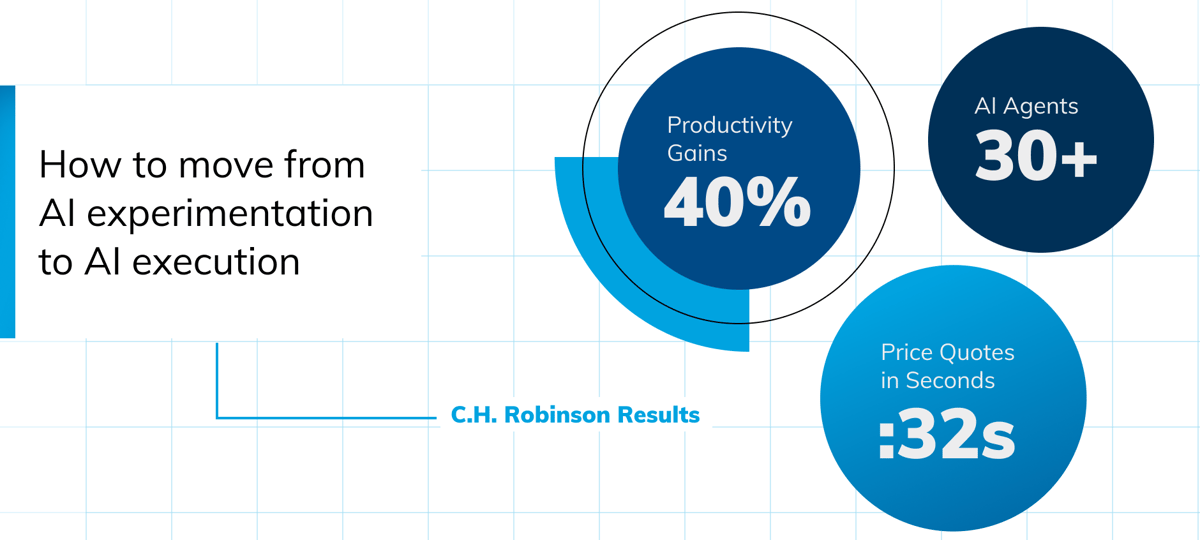

C.H. Robinson — a 120-year-old logistics company orchestrating supply chains for 83,000 customers worldwide — has cracked how to move from AI experimentation to AI execution. The numbers tell the story: 40% productivity gains, 30+ AI agents processing more than 3 million tasks, price quotes in 32 seconds instead of hours. The company has delivered seven consecutive quarters of market outperformance, more than doubling its stock price during an industry downturn.

“This isn’t just experiments,” says C.H. Robinson CEO Dave Bozeman. “It’s actually bottom line results.”

The result is a playbook that's reshaping global supply chains — and offering lessons for every industry trying to move AI from promise to performance.

A Lean Framework

The transformation at C.H. Robinson didn’t start with technology. It started with process.

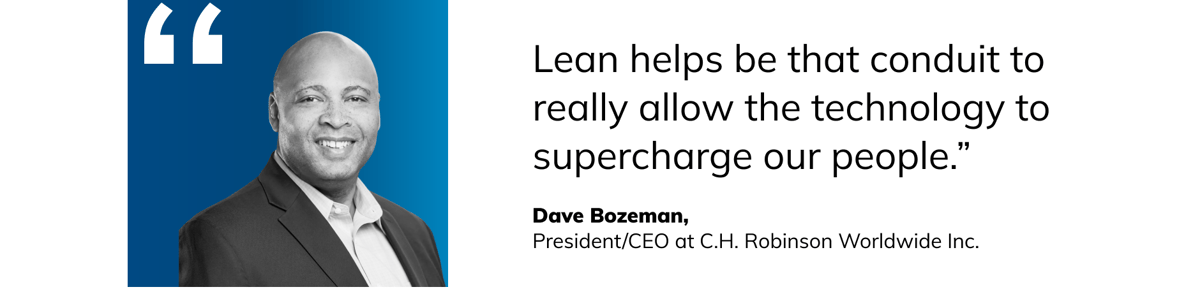

When Bozeman took the helm as CEO in 2023, he brought a framework that’s rarely associated with cutting-edge AI: Lean manufacturing principles. A self-described “Lean practitioner,” Bozeman saw that AI's failure in most organizations wasn’t a technology problem, but an execution issue.

“Lean is about continuous improvement,” explains Bozeman, who honed Lean principles at Ford, Amazon, Caterpillar and Harley-Davidson. C.H. Robinson calls its approach “Lean AI” — fusing Lean principles with AI technology to improve flow, remove waste from systems and drive accountability and performance. The approach pairs advanced AI with the expertise of the company's logistics professionals — technology and human insight working as one system.

C.H. Robinson mapped its quote-to-cash workflow — the process from customer inquiry to payment — identified bottlenecks and waste, then deployed AI agents that worked with precision to automate routine tasks. The result: logistics experts freed to focus on complex, strategic problem-solving for customers like navigating shifting trade policies and weather disruptions, consolidating inventory more strategically and decreasing costs and risk while AI handles repetitive execution. This all delivers smarter, faster and better supply chains that are constantly improving.

Bozeman describes the fusion as a “radioactive spider” that connects process discipline with AI, turning data into action. The technology is woven into the company’s operating model itself, which means AI amplifies what employees already do well rather than circumventing existing workflows.

The approach stands in contrast to how many companies pursue AI: technology first, searching for problems to solve second. C.H. Robinson mapped the problems, then engineered solutions.

From Gen AI to Agentic

In 2024, C.H. Robinson made the big leap that many companies are still contemplating: the shift to agentic AI.

The distinction is critical. Generative AI automates structured tasks within defined systems. Agentic AI introduces reasoning — allowing AI agents to work across systems, handle imperfect inputs and make decisions in real time. For a company managing 37 million shipments annually across fragmented data sources, the implications are transformative.

The decision to move to agentic AI happened with unusual velocity. When the need to move faster surfaced during an executive review, C.H. Robinson made the call in three weeks. “Historically, a decision like that might have been a two-year process,” Bozeman notes.

The speed reflects a combination of operational readiness and a conviction that waiting to scale working AI would be riskier than moving quickly to leverage the technology. “The technology is able to learn — it’s able to see, it’s able to reason,” Bozeman says. This capability allows AI agents to go off-system — pulling intelligence from phone calls, emails and other unstructured sources that have historically defied automation.

In September alone, one AI agent captured 318,000 freight tracking updates from phone calls — data previously invisible to the company's systems. That information now flows to other agents that update the platform, feed predictive Estimated Times of Arrivals and optimize deliveries. The company calls this digital teammate the Always-On Logistics Planner™— connected AI agents resolving issues in real time across geographies and transportation modes.

“Customers’ needs are dynamic, and supply chains are complex and imperfect,” Bozeman says. "Agentic AI allows you to solve imperfect inputs.”

The Leadership Imperative

Bozeman is passionate about not just delegating AI transformation to technology teams. Business leaders should be directly involved in the process. “You need to become hands-on,” he says. “That means going deep and understanding your workflows, understanding your data.”

Bozeman spent time on the floor, observing workflows firsthand. Understanding the actual work was essential to changing how the organization approached problems — “driving this sense of we're no longer going to prosecute the person, we're going to prosecute the problem,” says Bozeman. When employees understood AI deployment was about solving process challenges rather than assigning blame, it opened up innovation. Early successes were highlighted and celebrated to reinforce the shift.

“This works when you lead from the top with conviction,” Bozeman explains. “As a CEO, I know that this cannot be a hobby. This has to be something that you drive.”

Many organizations also chase multiple use cases simultaneously — diluting focus and obscuring impact. C.H. Robinson succeeded by concentrating resources on high-impact processes.

The approach transfers broadly. “Whether you're in a back office or you're in a manufacturing facility, how do you look at your process and eliminate the wasteful elements?” Bozeman asks. “That could be on just about anything that you produce or a service that you provide.”

Whether manufacturing, healthcare, or financial services, the playbook is the same across industries: understand the work, streamline operations, amplify with technology.

Breaking through requires more than investment. It requires rethinking how work gets done.