In Business, Better Connectivity Means Better Productivity

Learn how 5G powers next-generation technologies like virtual reality to transform enterprises in the first installment in this series co-created by Ericsson and Bloomberg Media Studios.

Imagine teams of workers, in different locations, using VR headsets to collaborate on a virtual, life-size replica of a car, battery or engine in real time. Picture robots moving products around a factory, freeing up workers to focus on other tasks. Envision smart clothing, like athletic sneakers that are continuously updated and modified based on an individual’s use.

Now, there’s a mobile network that enables all of this—and more.

Connectivity is the driving force behind innovation, powering the technologies of tomorrow. We’re able to do things now that we couldn’t have imagined even a few years ago, and in the not-so-distant future, we’ll be able to do more. The evolution began with 4G on the consumer side, powering smartphones and apps, and creating a huge business ecosystem. The current evolution is most pronounced in business, as every industry is being reshaped by 5G-powered technologies that create more productive ways to work.

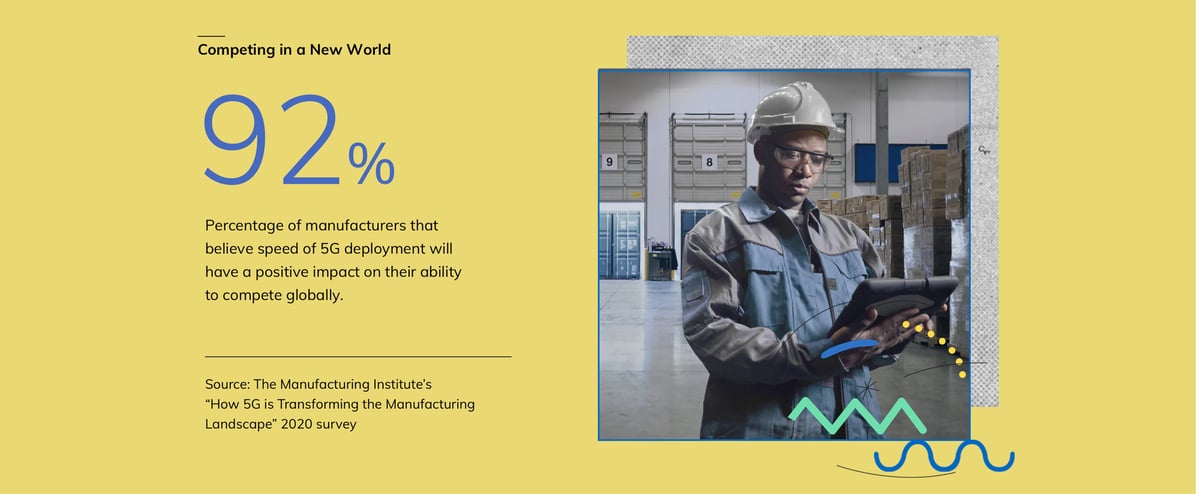

“5G is really going to help transform the work that we do and our ability to compete in a global economy,” says Carolyn Lee, President of the Manufacturing Institute, a nonprofit workforce development and education partner of the National Association of Manufacturers, the largest U.S. industrial trade group.

The business case for 5G

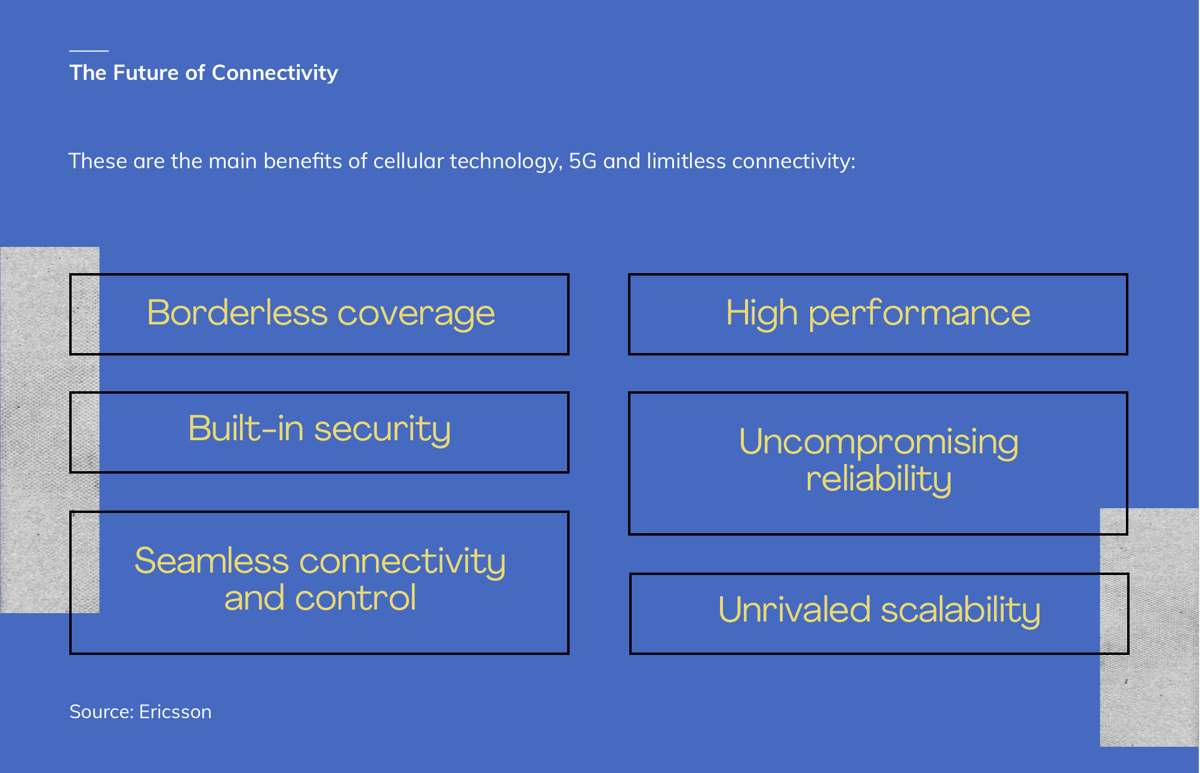

5G, the fifth-generation wireless cellular network, greatly boosts the speed and responsiveness of wireless networks. Up to 100 times faster than 4G, 5G also enables a sharp increase in the volume of data transmitted over wireless systems due to more available bandwidth and advanced antenna technology. Another key benefit is 5G’s near-immediate network response time, or low latency.

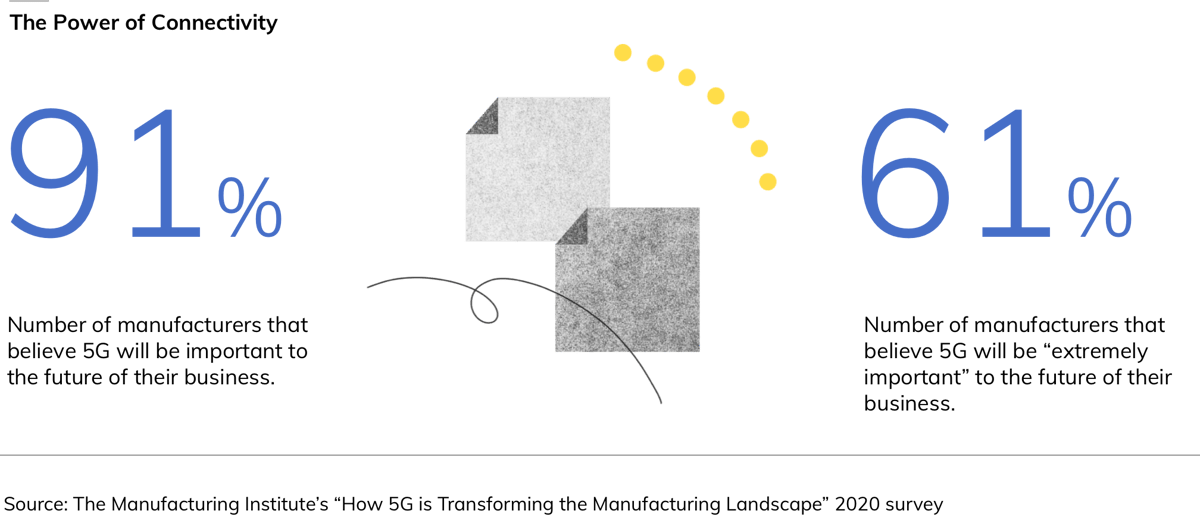

For businesses, these advantages are a catalyst for innovation. In fact, three-fifths of manufacturers believe that 5G will be “extremely important” to their business, according to a survey by the Manufacturing Institute.

The future of manufacturing, realized

Some manufacturers are already using 5G to build smart factories. Ericsson opened its first highly automated smart factory in 2020 in Lewisville, Texas. The Ericsson USA 5G Smart Factory, which produces 5G equipment for deployment across North America, utilizes many next-generation technologies.

At the factory, 5G improves the efficiency and safety of autonomous mobile robot (AMR) operations. AMRs, which move components and finished products across the production floor, can respond to requests within a matter of seconds, allowing materials to reach their destination faster. They are also equipped with sensors to detect obstacles on the floor. If the sensors detect an obstacle, the AMR automatically stops, avoiding a possible accident.

Paul Tse, the factory’s 5G Customer Relations Manager, says that 5G is crucial for many technologies at the factory, including the AMRs. “5G frees us because you don’t have to wire things, and you get the bandwidth to have smarter sensors,” he says. “Often, Wi-Fi works great when you’re doing proof of concept, but when you have, say, hundreds of machines, you run out of bandwidth or you have interference.”

Technology bridges the distance

Another example of how 5G can help transform manufacturing is Hyperbat, a joint venture between Williams Advanced Engineering and Unipart Manufacturing Group. As the UK’s largest independent vehicle battery manufacturer, Hyperbat has been working alongside partners—BT, Ericsson, Qualcomm, NVIDIA, Masters of Pie and The Grid Factory—to help its design and engineering teams collaborate on prototypes located in two locations over 100 miles apart.

The design and engineering teams at Hyperbat have been able to collaborate using 5G, VR and digital twins—digital representations of physical objects—in real time, which allows teams to interact with a life-size 3D hologram virtually and simultaneously. The project’s key enablers are the high speed, low latency and large data handling capabilities of the Ericsson 5G private network deployed by BT.

What’s next?

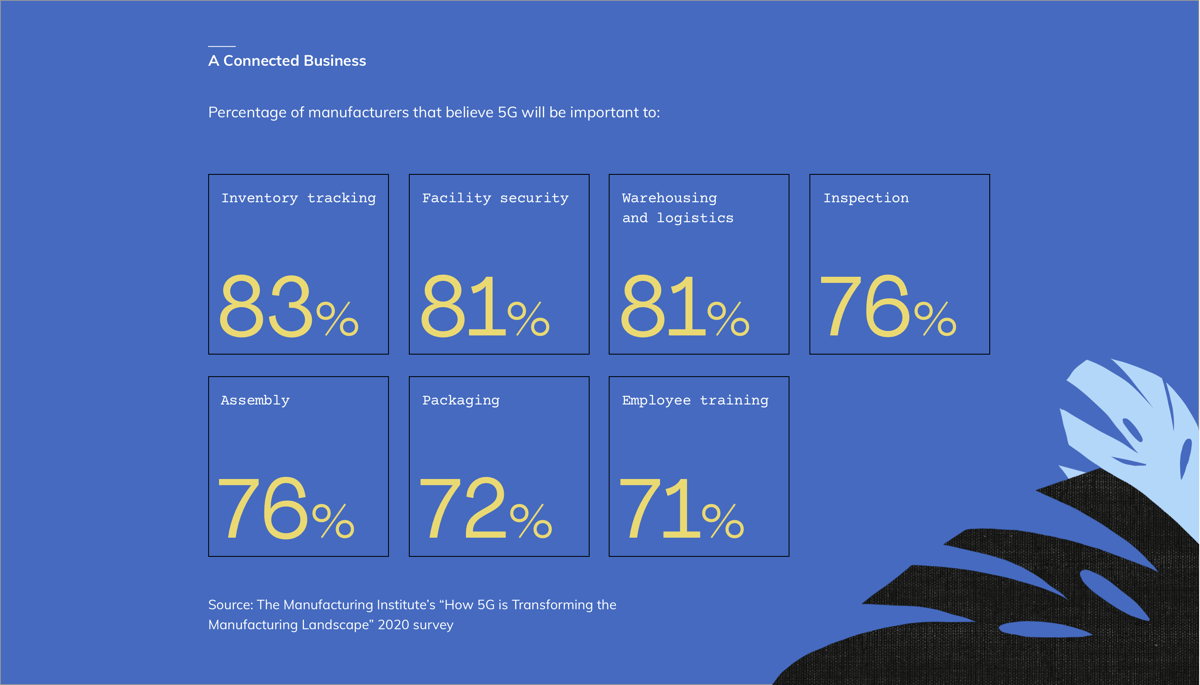

With 5G, boundaries disappear and possibilities become endless. For instance, today, most companies use manual controls to track and trace products. Using 5G, logistics companies can label, track and record shipments automatically and more easily address issues such as lost cargo, misplaced containers, counterfeiting and smuggling. 5G also can transform supply chain operations by ensuring more efficient collection and delivery of products. And once you improve operations, it’s easy to imagine that factories will become smart, agile and adaptable enough to manufacture products that are needed locally, based entirely on quantifiable demand.

Consumer-focused industries will discover new tools which could, for instance, help the production of clothes that are personalized and sized for individual customers. Smart clothing will feed a wealth of digital data to developers, designers and engineers to give them unprecedented understanding of performance and issues so they can constantly perfect the design. Smart clothing could also help inform the future buying choices of customers: running shoes could analyze a wearer’s stride, then recommend the ideal pair when the time comes to replace them – and maybe even allow the wearer to digitally try the new pair on through haptic technology.

Meanwhile, consumers will benefit from digital alerts, upgrades and modifications that go far beyond anything they currently receive. This is made possible through AI, where the network acts as an extension of the system, thinking, correcting and adapting in real time to maximize the quality, safety and efficiency of connected systems. Some brands already are testing smart fabrics that can collect data. These products can be connected with 5G, enabling real-time data that provides near-instant feedback to the wearer; ultimately, consumers could maintain a digital wardrobe.

“Real-time data is the future of manufacturing,” says Carlos Torres, Head of Industry 4.0 at the Ericsson USA 5G Smart Factory. “5G provides the connectivity we need for machines to ‘talk’ with one another and respond quickly to those insights."

Of course, 5G isn’t a destination, but a major upgrade on the network journey, and research is ramping up for 6G and beyond as emerging technologies present new challenges and push connectivity limits. Ericsson is looking into the future of 6G and beyond, and the technologies they will power. For example, Ericsson has teamed up with MIT to explore the concept of batteries that never need to be recharged or replaced, but rather harness energy from their surroundings—and transform industries in the process.