Go Green to Grow

The current squeeze on energy supplies that has seen global fuel prices soar could have a silver lining: accelerating the switch to renewable sources of energy.

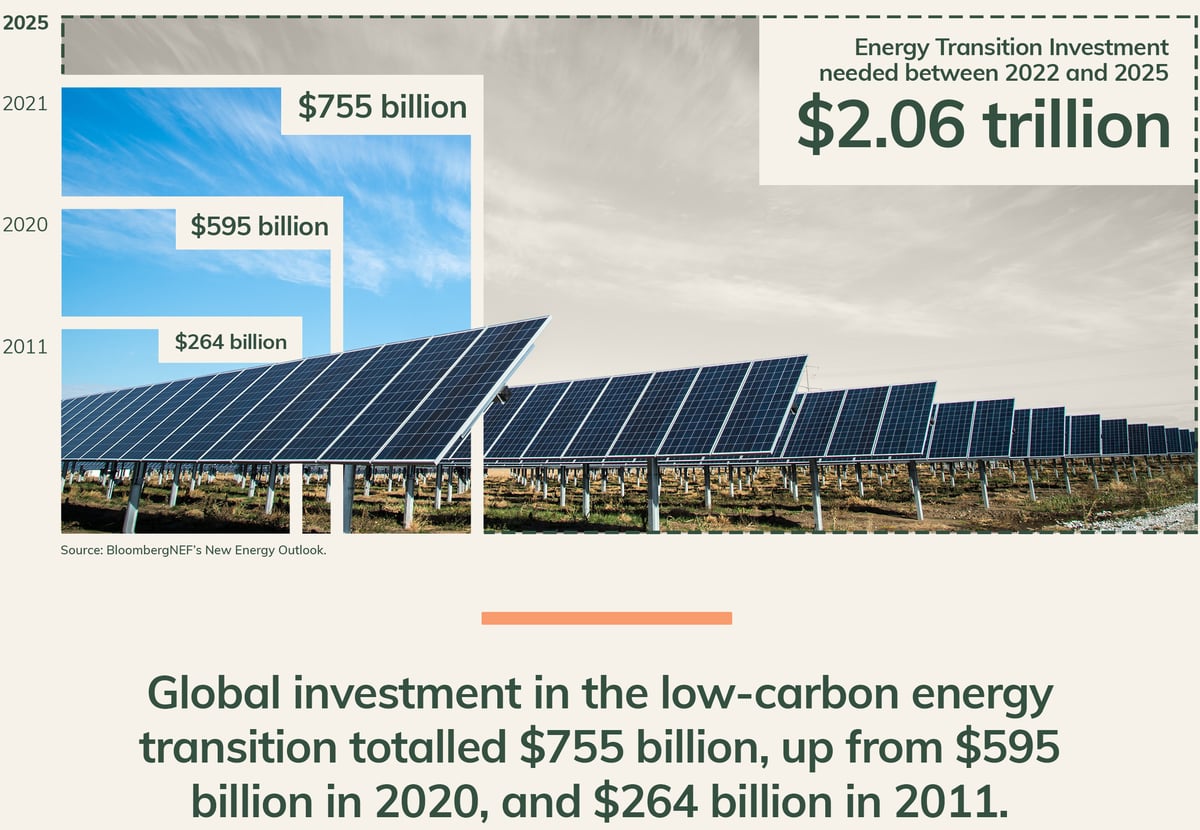

Last year, global investment in the low-carbon energy transition totaled $755 billion, up from $595 billion in 2020, and from $264 billion in 2011.1

However, to get on track for global net-zero carbon, energy transition investment will need to average $2.06 trillion between 2022 and 2025, according to BloombergNEF’s New Energy Outlook.2 That’s around three times what it was in 2021.

For Hanwha, a global energy solutions provider and a Fortune Global 500 company, a more sustainable future depends on the development of technologies that will minimize the current reliance on fossil fuels.

“If we can make changes in the way we produce, harvest, and utilize energy, the impact will be immense,” said Dong Kwan Kim, CEO of Hanwha Solutions.

“That’s why we’re so committed to bringing new climate technologies in solar and hydrogen arena to the world and making them more accessible, so we can work together to fulfil our mission to create ‘sustainable solutions for Earth, for life.’ ”

With the climate-change clock ticking amid increasing threats to our energy security, the race is on to identify the clean energy sources that offer the most practicable alternatives at scale.

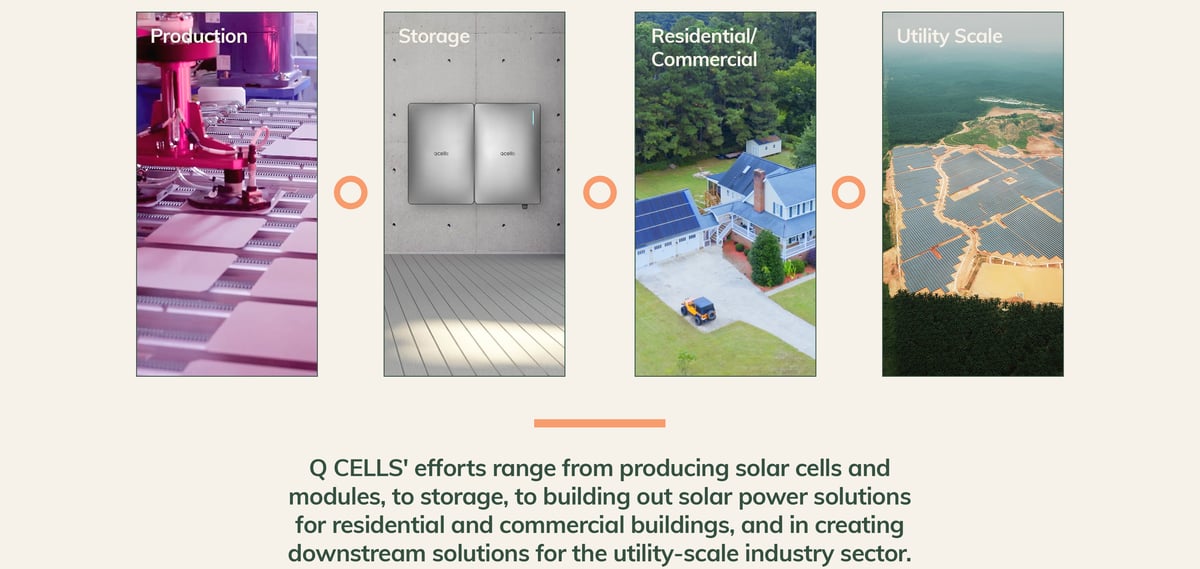

Hanwha, through its Q CELLS business, has established itself as a global leader in solar energy. Its efforts range from producing solar cells and modules, to storage, to building out solar power solutions for residential and commercial buildings, and in creating downstream solutions for the utility-scale industry sector. But now it’s expanding its focus by securing capabilities across the wider solar technology supply chain in an effort to make it greener and strengthen energy security. While solar power generation itself doesn’t produce emissions, the process to create solar technology – from raw materials extraction to manufacturing – can still have a carbon footprint.

For this reason, Hanwha recently acquired a controlling stake in REC Silicon, which operates a plant in the United States that produces polysilicon – a key raw material in photovoltaic systems – using hydropower-based clean energy. Compared to carbon-heavy polysilicon manufactured elsewhere using fossil fuels such as coal, REC Silicon’s “clean polysilicon” is expected to see growing demand as international scrutiny over industrial emissions intensifies.

With its 1.7-gigawatt solar module production capacity already in operation and an additional 1.4 gigawatts on the way, Hanwha is one of the largest solar manufacturers in the US. And with its new focus on investing in companion businesses along the supply chain to ensure they adopt the same standards, Hanwha will help to drive greater stability and consistency in the US solar market.

“Increasing energy market turbulence tells us why securing key raw material production is so critical,” said Justin Koo Yung Lee, CEO of Hanwha Solutions Q CELLS Division.

“Given upward pressure on oil prices and environmental scrutiny over the environmentally damaging impacts from fossil fuels, we believe that strengthening the renewable-based energy supply chain is important – and producing low-carbon solar material is a good starting point to achieve the goal.”

Hydrogen is another attractive fuel source given that it produces only water vapor when burned, making it attractive for industries such as steel, chemicals and aviation that are trying to reduce their carbon footprint. The Hydrogen Council, a global CEO-led initiative of leading energy, transport, and industry companies, expects hydrogen energy technologies to provide 18% of the world's total energy needs by 2050.3

However, most of the hydrogen currently used by industries like these comes from converting natural gas in a process that releases large quantities of carbon dioxide. About 95% of the world’s hydrogen is currently produced using fossil fuels in a process called steam methane reforming. And for each kilogram of hydrogen it generates, it produces seven kilograms of carbon dioxide.4

Hanwha is currently working on the low-carbon production of “green hydrogen” through electrolysis, a combustion-free process in which an electric current is run through water to split it into its constituent hydrogen and oxygen atoms among other methods.

“We are developing efficient and economic electrolysis technologies to produce green hydrogen from water, while leveraging renewable energy through our solar solutions,” said Charles Hee Cheul Kim, CEO of Hanwha Impact and Hanwha Energy. “But we do expect that some time will be necessary before the process can be commercialized and adopted at scale.”

According to the International Energy Agency, global hydrogen demand needs to reach 530 million tons by 2050 in order to meet global Net Zero targets.5 Last year that number was 90 million tons, and green hydrogen made up less than 1% of that.6

As a result, Hanwha is pressing ahead with hydrogen solutions that can power growth in the more immediate term by working within existing fuel infrastructure.

But Hanwha is not stopping there. It plans to eliminate emissions completely.

“So far, we’ve succeeded in Europe and the United States in retrofitting commercial gas turbines that now burn up to 35% hydrogen by volume,” said Charles Hee Cheul Kim. “There are two new projects ongoing. The first is a demonstration project in Korea where we are relocating and recommissioning a previously retired 80-megawatt gas turbine. The turbine will be retrofitted and refurbished to run on up to 50% hydrogen starting early 2023.

“In the US, there is also a cogeneration plant in New Jersey where our technology is being used to modify a 172-megawatt turbine. For the first time in the world, a 40% hydrogen co-firing rate will be applied to natural gas turbines in commercial operation.”

The co-firing rate refers to how much hydrogen can be burned in a turbine – the hydrogen-to-natural-gas ratio.

While this innovation is a huge step forward, weaning the world off its dependence on fossil fuels and transitioning to a plentiful supply of cleaner alternatives led by solar and hydrogen will take a collective effort.“Cross-sector collaboration between government, civil society, and the private sector is truly at the center of shaping the global climate agenda,” said Dong Kwan Kim.

“Hanwha will continue to pursue cross-sector collaborations and public engagement that inspire concrete, greener practices in every corner of life.”