Where Sustainability Is Second Nature

More than 10 billion passengers will travel by plane in 2050, up from 4.56 billion in 2019, according to the International Air Transport Association (IATA). Demand for jet fuel is projected to double in lockstep, potentially adding to the carbon footprint of the aviation sector, which is already responsible for 2.4% of global CO2 emissions, according to the IATA.

In the face of such projections, how can any airline expect to become carbon-neutral? Climate action begins by charting a direct, attainable emissions reduction path – one as clearly defined as the route from JFK to MUC. It requires designing a reduction path validated by the Science Based Targets initiative (SBTi) and aligned with the goals set at the Paris Agreement to keep global temperatures from rising another 2 degrees Celsius.

Fortunately, the aviation industry’s centralized distribution networks mean that commitments made at one organization can have a sector-wide ripple effect. For Lufthansa Group, leadership takes the form of its commitment to halve net CO2 emissions by decade’s end (and thereby have a SBTi-validated reduction agenda to meet Paris) and adopting a multi-pronged approach to sustainability. It’s a model where no solution is too big or too small, and where inspiration can be found in the most unexpected places – like the skin of a 450-million-year-old fish.

An innovation with teeth

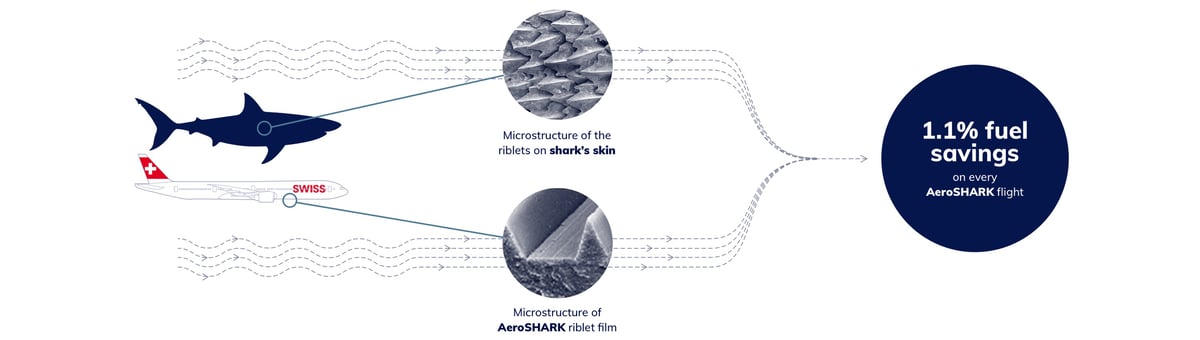

The aviation industry has been researching ways to reduce aerodynamic drag for years, and the solution may come from prehistory. AeroSHARK, a bionic film developed in collaboration with BASF, mimics shark skin to reduce a plane’s friction in the air.

Applied to the belly of aircraft, such as Lufthansa Cargo or SWISS aircraft, the film is covered with millions of prism-shaped riblets, each just 50 micrometers high. AeroSHARK is currently rolled out on Lufthansa Cargo’s and SWISS entire Boeing 777 fleet where it is expected to translate to an annual fuel savings of 1.1% and a reduction of 26,800 tons of CO2 emissions.

Jet fuel, with a dash of trash

Currently available propulsion technologies can’t eliminate carbon emissions at the point of combustion, which means that what powers the aircraft is the key to decarbonization. (Small battery-powered aircraft may be available by decade’s end, but they won’t add value to network carriers or those flying routes of 75 miles or more.)

This makes the adoption of Sustainable Aviation Fuel (SAF) the main way for the industry to decarbonize as it continues to grow, as SAF can already work within existing global infrastructure.

First, the good news: SAF used by Lufthansa Group can reduce life-cycle carbon emissions by at least 80%, according to Bloomberg New Energy Finance. The bad? IATA reports that in 2019, SAF represented just 0.1% of global jet fuel demand, and global production reached just 12.5% of operational capacity as a result.

Lufthansa German Airlines was using second-generation biofuel – kerosene produced from used vegetable oil or residual agricultural biomass – as far back as 2011. But this market is a developing one. Electricity-based fuels like Power-to-Liquid (produced using water and electricity from renewable sources and carbon captured from the atmosphere or collected directly from carbon sources) are on the horizon.

Turning sunlight into fuel

In August 2022, Switzerland-based Synhelion became the first company in history to successfully produce synthetic gas at scale using only solar heat as the energy source, clearing the final technical hurdle to producing the ultimate carbon-neutral jet fuel.

The Sun-to-Liquid process works by carbon capture, extracting CO2 from the atmosphere and mixing it with water and energy produced by a concentrated solar power (CSP) mirror array and receiver tower, resulting in syngas that can be converted into liquid kerosene. The very definition of carbon-neutral, Sun-to-Liquid can only ever release as much CO2 as went into making it, and SWISS is set to become the first airline to power flights with solar kerosene from 2023 onwards.

Solar Kerosene at Scale

Synhelion’s first field in Julich, Germany, has the capacity to produce about 150,000 liters of liquid solar fuel per year.

A fork that grows faster

Lufthansa German Airlines, SWISS and Austrian Airlines have all adopted algorithm-based meal-demand planning, which limits food waste by ensuring that only the amount needed is on the plane in the first place.

Every little bit helps when it comes to plane weight, and this extends to letting passengers take part in sustainability initiatives. As of last year, that includes giving Lufthansa flyers access to compostable cutlery made from fast-growing bamboo (which absorbs 4x more CO2 than wood).

In 2019, Lufthansa Group unveiled the Compensaid program to allow passengers to opt for carbon-neutral flying. With just one click on the airline group’s website, it’s now possible to make carbon-neutral choices the default option. In this way, Lufthansa Group ensures that passengers can play an active role on the journey to carbon neutrality.

Such power of choice is indicative of the need to empower everyone, from the passengers who travel on planes to the engineers who design them. In the face of a singular challenge like climate protection, diverse solutions must be embraced. The aviation industry is taking steps to encourage this transformation, leaning on technology and innovation, investment and inspiration, passion and conviction to chart the course ahead.