The Problem-Solving Science

How innovation in chemistry will connect, inspire, and create a better world.

Today’s world, and tomorrow’s, are built on chemistry. Technology may get the headlines, but it’s chemistry that makes possible the coming revolution in zero-emission green hydrogen energy, powers electric vehicles, and enables 5G networks to turn advanced electronics into connected devices that form the Internet of Things.

“Chemistry is essential to almost everything we use in our lives every day,” says Natalia Duchini, Global Technology Senior Director, Thermal & Specialized Solutions at The Chemours Company, a global leader in titanium technologies, thermal and other specialized solutions, and advanced performance materials. “It’s an enabler of technology that powers simple and complex machines of every type. That’s powerful. If you’re not investing in chemistry, you’re not investing in technological innovation or the manufacturing processes behind it,“

Innovation in chemistry is desperately needed. Projections suggest that by 2050, more than two-thirds of the global population will live in cities. Those new urbanites—many living in megacities of over 10 million people—will demand clean energy, lower emissions and more efficient transportation, along with advanced electronics and connectivity to power these commercial and cultural centers.

This need is driving megatrends in connectivity, transportation, and energy that are shaping the future of the world’s climate. Innovators such as Chemours, in partnership with customers and communities, are applying advanced chemistry to provide transformative solutions. One of these transformations is playing out right now: the full realization of a connected world powered by 5G and advanced electronics.

“If you’re building for a clean energy future and you’re not investing in chemistry, you’re missing the mark.”

Today’s Megatrend:

The 5G World, Connected by Chemistry

It’s estimated that there will be 18 billion mobile devices—2.2 for every human on Earth—by 2025. As this number grows, so does our dependence on them. Daily life relies on smart devices operating at ever-faster connection speeds. But 5G isn’t just for phones—it’s a whole ecosystem that provides seamless connections for smart devices inside homes, vehicles and workspaces. Chemours chemistry is integral to the development and adoption of 5G worldwide.

5G enables a whole ecosystem of connected smart devices in homes, vehicles and work and play spaces.

The Wilmington, Delaware-based company believes that its chemistry-driven solutions will support the wide adoption of 5G. “If we want to get to where we achieve higher speeds and broader adoption, we need more manageable processing materials that provide an overall lower cost of ownership and are more capable than existing materials,” says Dr. Randal King, Vice President of Technology at Chemours. “That’s where advanced chemistry comes in. As we develop better materials, we can help accelerate the adoption of these new technologies.”

Chemours chemistry is integral to the development and adoption of 5G worldwide.

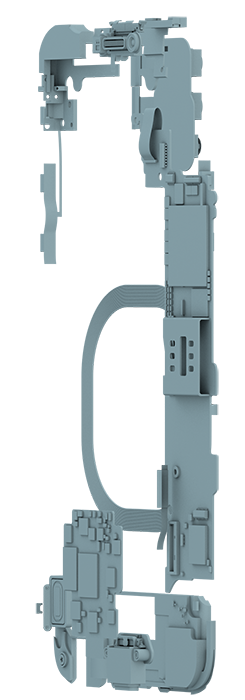

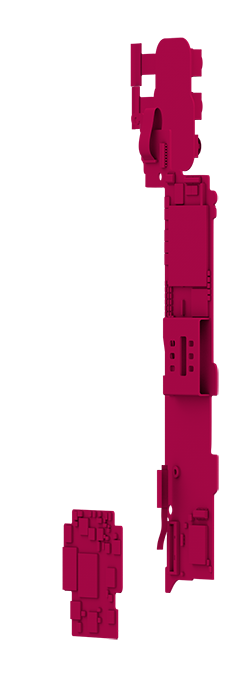

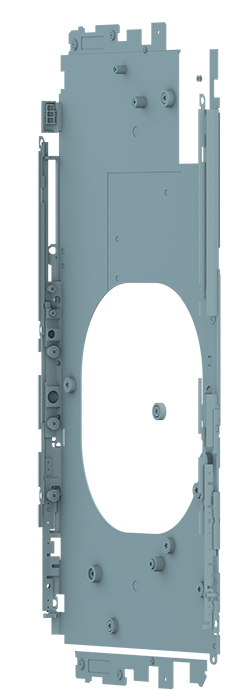

The journey to cost-effective 5G starts inside smartphones and other mobile devices, where state-of-the-art circuit boards and semiconductors provide our connection to the digital world. Chemours’ high-performance fluoropolymer resins and coatings make it possible to manufacture the advanced chips and printed circuit boards that 5G speeds require. The chemically inert Teflon™ fluoropolymers that Chemours manufactures can handle the high-purity chemicals and high temperatures found in semiconductor fabrication, ensuring that today’s increasingly advanced semiconductors perform efficiently and with optimal connectivity to maintain 5G’s high data transfer speeds.

The Chemistry of Communications

Smartphones are marvels of communications—and of chemistry. If it weren’t for a whole portfolio of advanced materials, we wouldn’t have these digital lifelines.

Today’s phones require small but mighty batteries to power larger screens and faster processors. Lithium-ion cells depend on fluoropolymers like Teflon™ to pack a lot of power in a tiny space.

Faster and faster semiconductors lead to more capable phones, but fitting that kind of processing power into such a small package requires precise fabrication. Teflon™ fluoropolymers make advanced semiconductor manufacturing possible—for phones and for our entire digital ecosystem.

Teflon™ fluoropolymers also underpin the whole 5G infrastructure, from cell towers to distributed antenna systems, enabling fast 5G protocols.

No other material can deliver the demanding performance required by today’s smart devices and networks.

Learn more about how Chemours’ chemistry is addressing the world’s expectations for higher performance from advanced electronics and connected devices now and in the future.

Tomorrow’s Megatrend:

A Revolution in Decarbonized Transportation

In addition to fast and connected advanced electronics and smart devices, the world’s urbanites demand clean transportation that keeps city traffic flowing without causing further climate problems. Fortunately, a new class of zero-emission vehicles are hitting the streets and roadways.

This transport revolution depends on chemistry, including a remarkable material: Chemours’ Nafion™ ion-exchange membranes, which allow hydrogen fuel cells to produce electricity without combustion or emissions.

Nafion™ membranes sit at the literal and figurative heart of the process and are the foundation for the development of hydrogen fuel cell electric vehicles (FCEVs).

FCEVs rely on fuel cells to combine hydrogen and oxygen electrochemically, producing nothing more than an electric charge and pure water vapor. This innovative technology gives FCEVs a longer range and offers faster fueling and better sustainability than lithium-ion battery-powered electric vehicles—especially when green hydrogen, produced with renewable energy, is used. Fuel cells are the ideal power plant for trucks and buses, which currently contribute 24% of transportation emissions in the U.S.

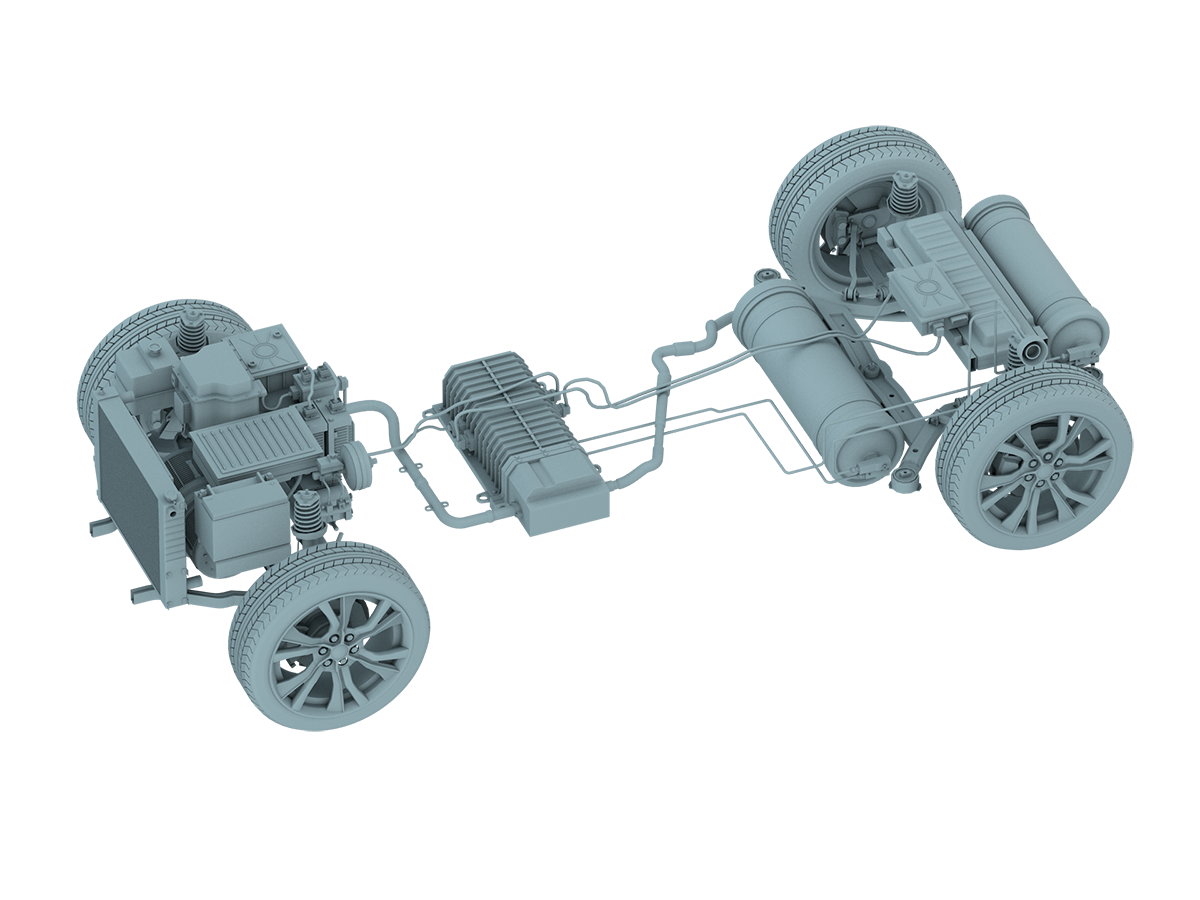

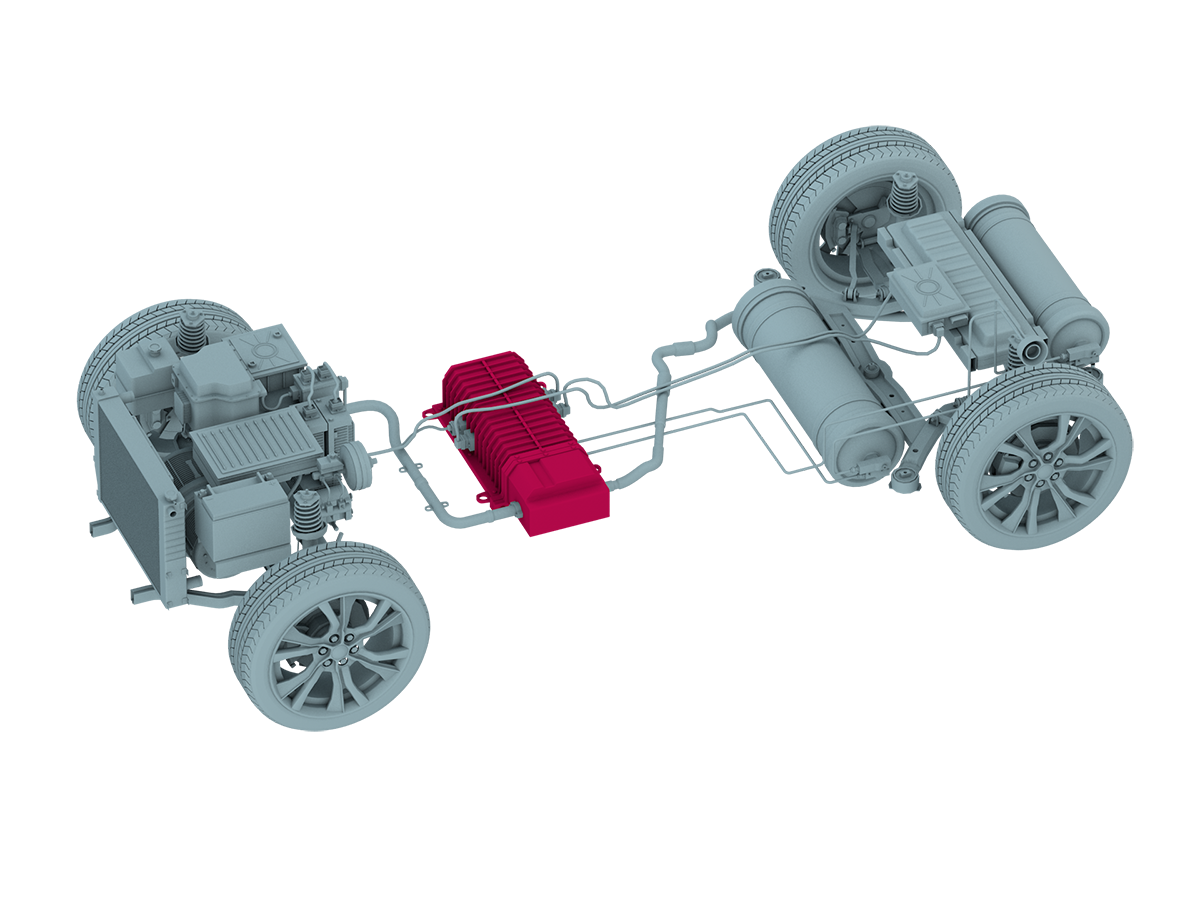

Electrifying Fuel Cell Vehicles

With climate concerns growing and technology improving, electric vehicles are becoming more popular. There is a new type of electric vehicle that can provide better range and free drivers from having to worry about charging stations. Meet the fuel cell electric vehicle (FCEV).

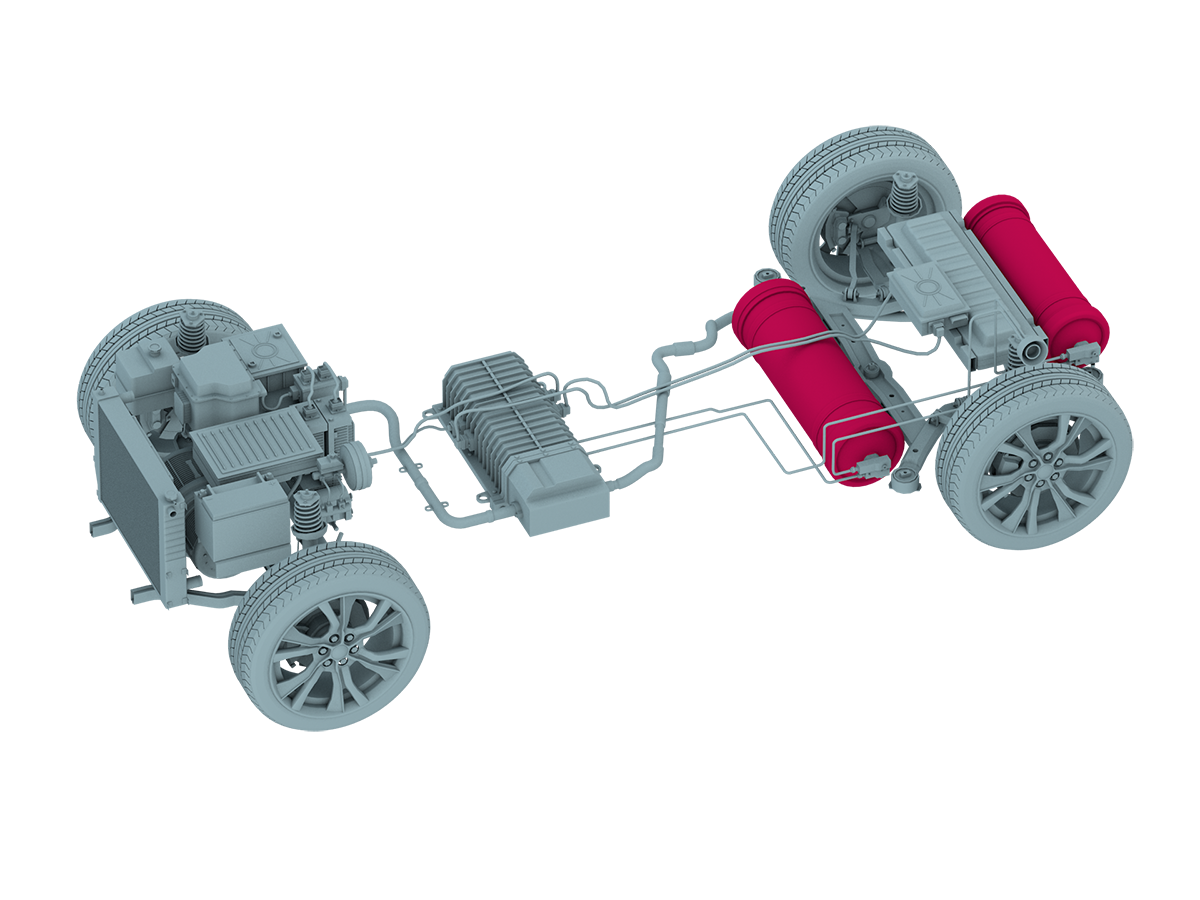

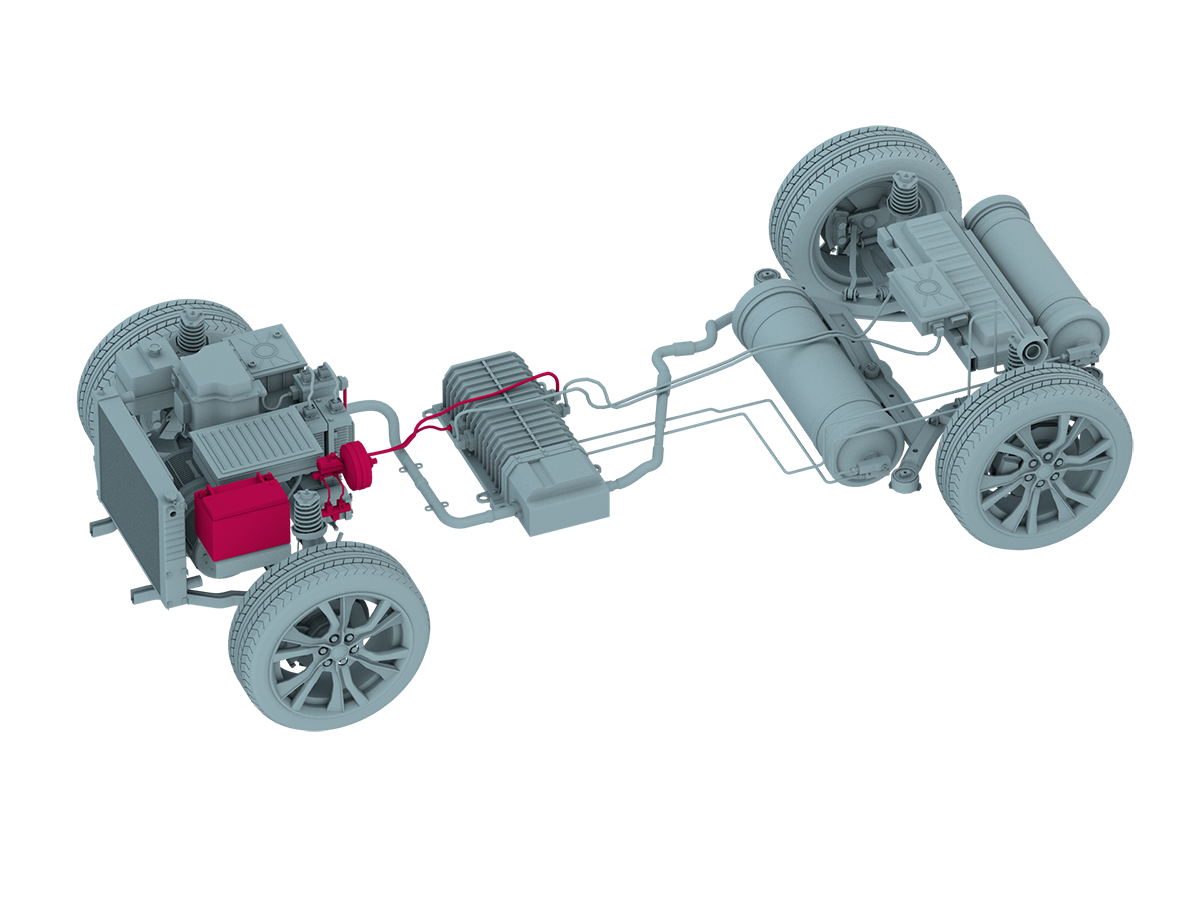

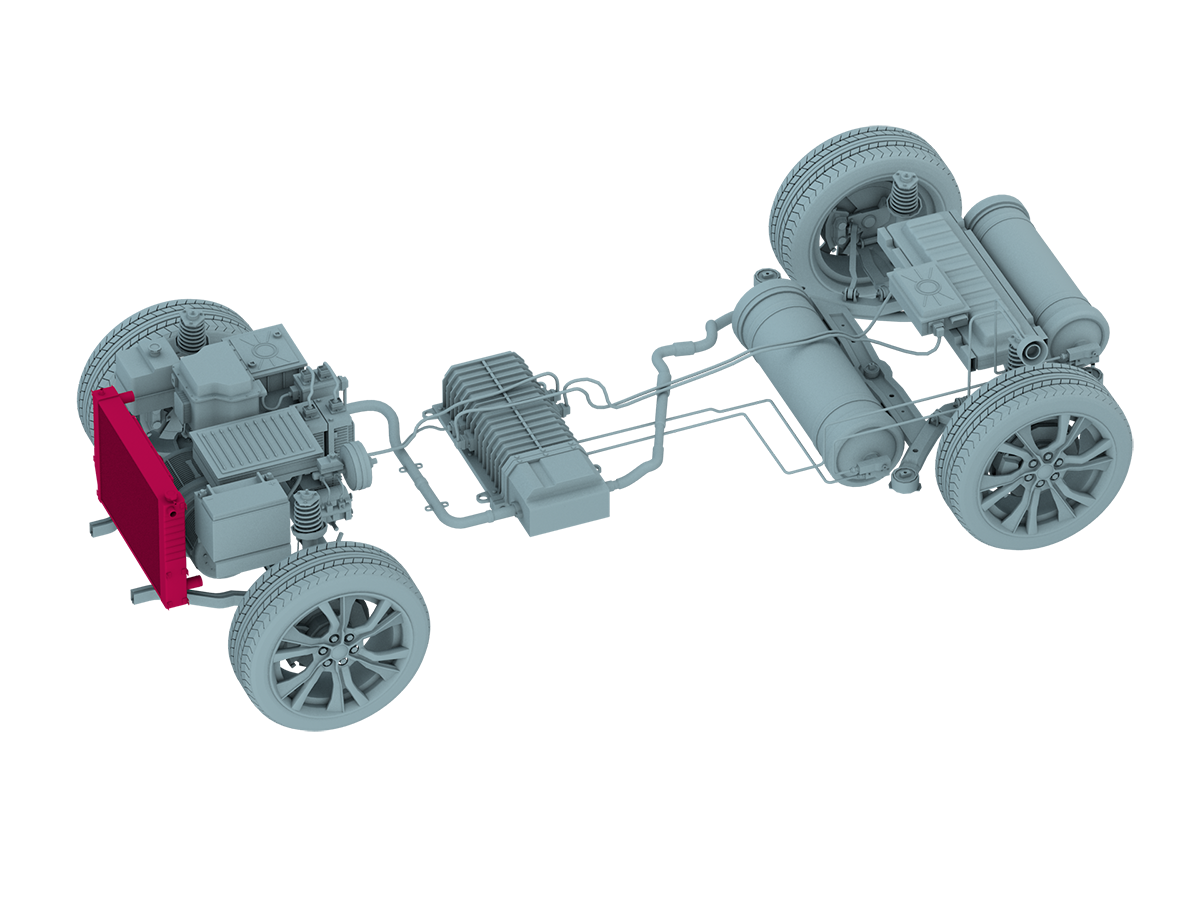

While battery electric vehicles must be charged externally, FCEVs carry ample amounts of fuel on board—just like a regular car. Instead of gasoline, they hold hydrogen kept in pressurized tanks. Fluoroelastomers like Viton™ and fluoropolymer greases like Krytox™ keep hoses and gaskets supple, durable, and tightly sealed so that this high-pressure fuel can move safely from the tanks to the fuel cells.

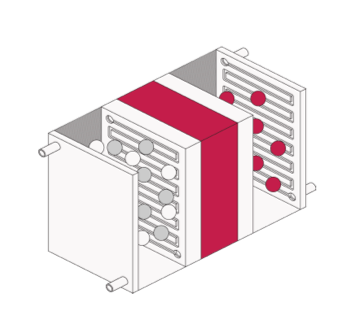

Once hydrogen reaches the fuel cell stack, something amazing happens. As the hydrogen passes through the cell, it encounters a catalyst-coated Nafion™ ion-exchange membrane that absorbs a charge from the hydrogen as it combines with oxygen. The result is an electric charge and pure water vapor—and nothing else.

The electric charge generated by the fuel cell gets routed to the batteries and to the electric motors that power the car by Viton™-coated high-voltage cables, keeping the electricity moving where it needs to go—safely.

No matter what powers them, vehicles need to keep occupants and components at ideal temperatures. New, low-global-warming potential refrigerants like Opteon™ charge vehicle heat pumps that keep things cool—or warm—without draining power.

The emissions savings of FCEVs are impressive when compared with conventional internal-combustion vehicles: According to the U.S. Department of Energy, fuel cell vehicles can reduce carbon dioxide emissions by up to 50% if the hydrogen is produced by natural gas, and by 90% if the hydrogen is produced using electricity from renewable energy sources such as wind and solar.

Backed by this strong sustainability picture, Chemours is investing in Nafion™ technology for fuel cells and other hydrogen applications. “The Nafion™ business is now the foundation of realizing the hydrogen economy and is looking to be critical in developing energy systems,” says Dr. William Raiford, Senior Director of Titanium Technologies at Chemours.

Achieving a clean energy future depends on chemistry.

While FCEVs may win out among commercial vehicles, consumers are increasingly opting for battery-powered electric cars. Manufacturers are responding with new models, many of which rely on solutions provided by Chemours chemistry: the power of Opteon™ refrigerants that make sustainable cooling possible, Krytox™ lubricants that lubricate moving parts and reduce noise for the life of a vehicle, and Teflon™, which protects everything from electronics to engines, and increases efficiency and longevity. Teflon™ membranes also protect energy equipment such as wind turbines and solar panels, which produce the renewable electricity that powers vehicle charging stations and green hydrogen—the megatrend that is disrupting the conventional energy economy.

China plans to have 1 million fuel cell vehicles on the road by 2030.

Source: Bloomberg Green

Although there is promising growth in battery-powered electric vehicles, many demands are being placed on the industry to ensure that these vehicles are affordable and practical for widespread consumer adoption. Many of these demands fall on the battery design, where incremental performance, manufacturing and cost improvements are needed.

Chemours has solutions to help solve many of these requirements, including the use of Teflon™ membranes as an electrode binder in lithium-ion batteries. Teflon™ membranes have the electrochemical stability that enables higher battery energy density and longer driving range. And Teflon™ allows for the use of a solvent-free electrode manufacturing process that reduces environmental footprint and costs.

Smart technology and sustainable innovation, learn more about how Chemours is defining the future of the automotive industry.

The Megatrend of the Future:

Green Hydrogen Will Change Everything

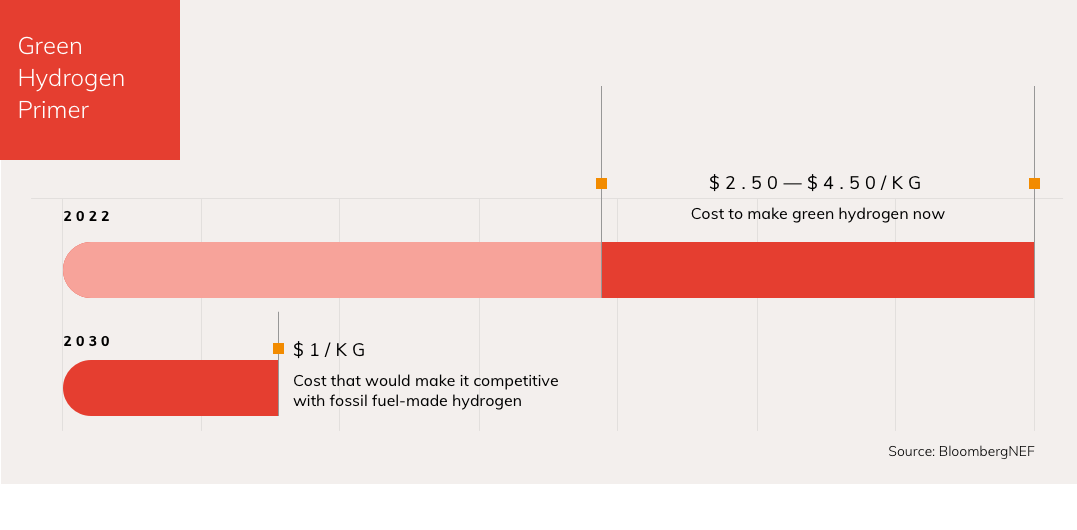

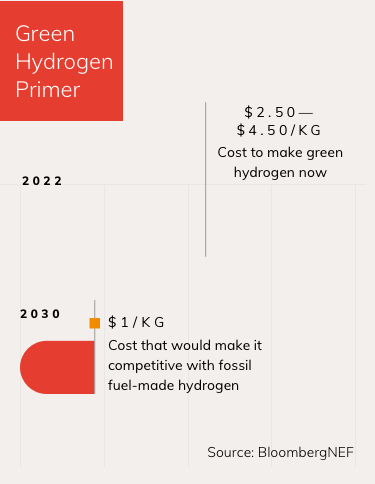

Most experts agree: Green hydrogen is the best fuel option for the future. Producing no greenhouse gas emissions, green hydrogen packs three times the energy, by weight, of oil and natural gas.

By 2030, according to a study by Oxford Economics, the world’s 750 largest cities will gain 220 million additional consumers. The smartphones, alternative-fuel cars, and heating and cooling systems that those new consumers acquire will require energy to build and power—energy the world can’t afford to generate from fossil fuels anymore.

Here’s where green hydrogen comes in. Chemically identical to fossil fuel-produced hydrogen, green hydrogen is made using a sophisticated electrolysis process that works like a fuel cell in reverse, combining Chemours Nafion™ membranes, catalysts, and renewable electricity to separate hydrogen and oxygen from water. Burning hydrogen produces pure water vapor and heat energy, which can be used just like any other fuel. Hydrogen can be stored with relative ease and transported by the existing gas grid, making it an ideal choice for heating homes and buildings, powering vehicles, and more. “The quality of life we enjoy today is not possible without chemistry. From helping to feed the world and keeping us connected to one another, to deep space exploration, chemistry contributes the lion share of these innovations. With chemistry, the possibilities are endless.” says Tekie Zeru, Vice President of Technology, Advanced Performance Materials.

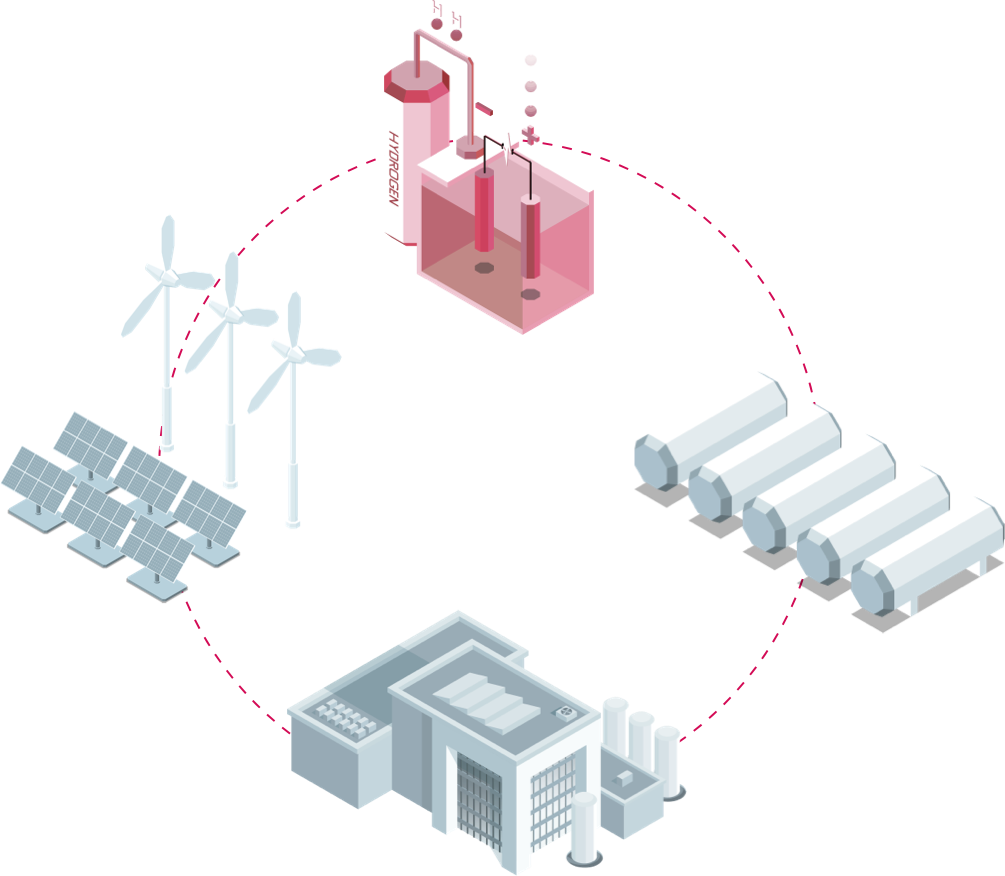

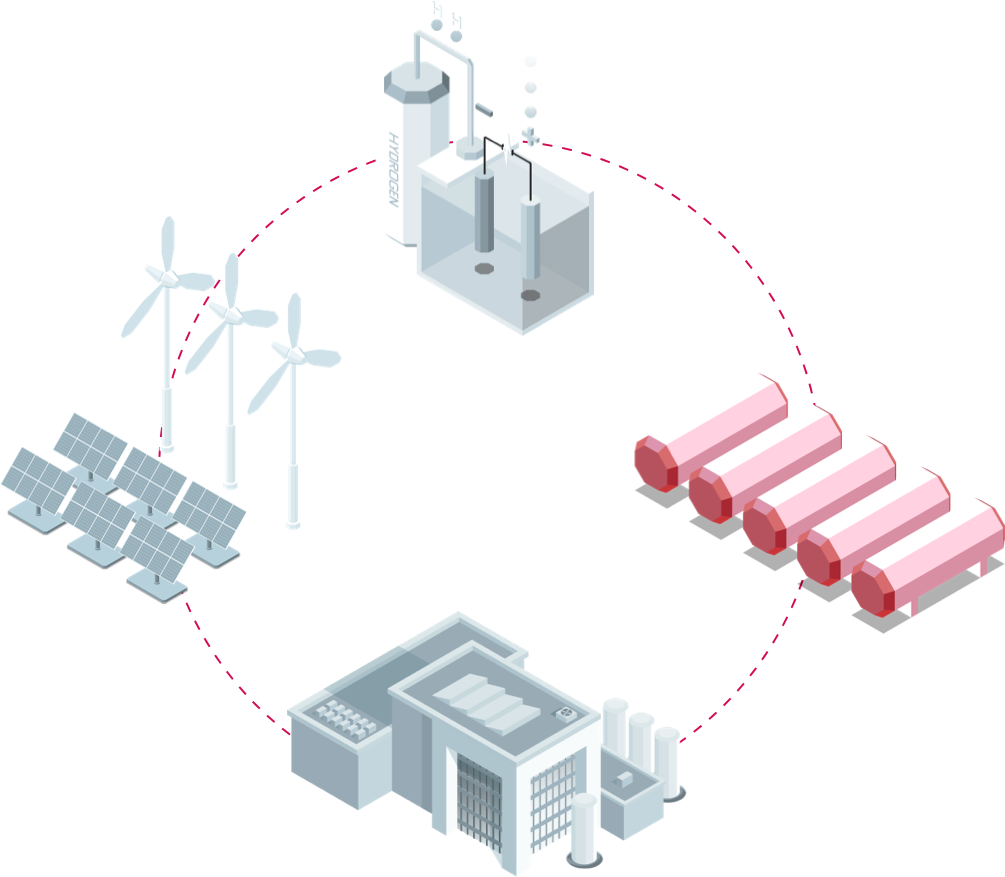

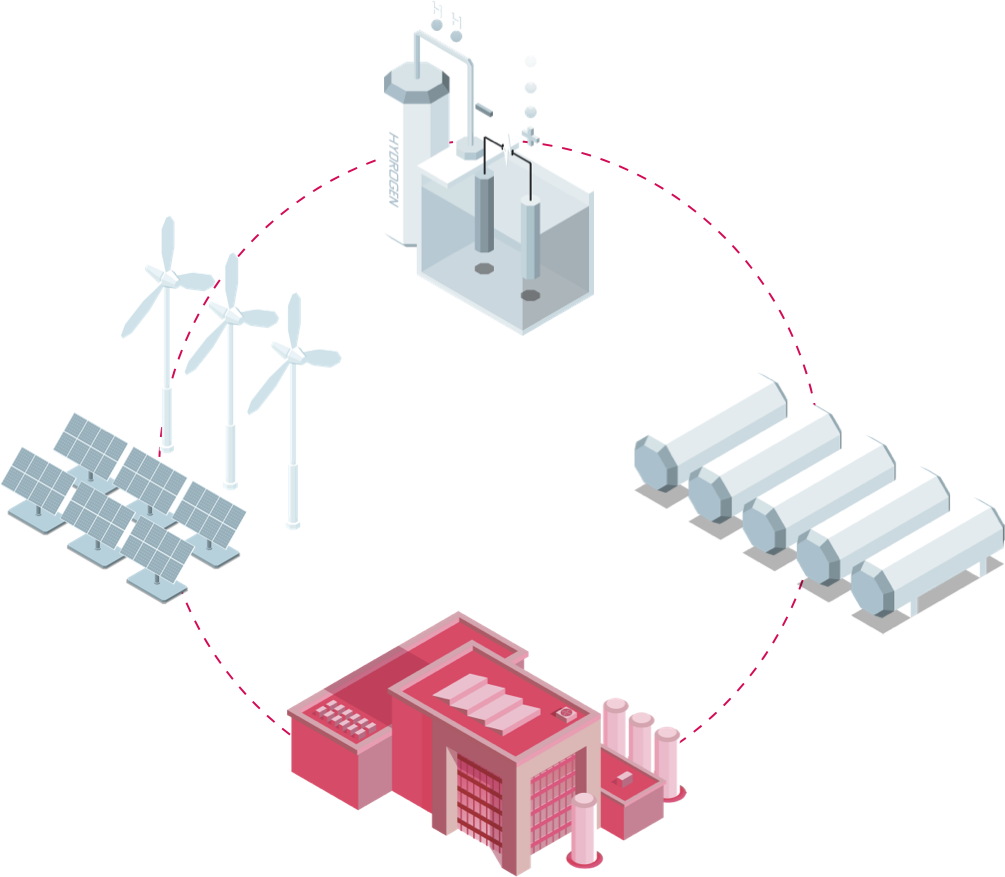

The Heart of the Hydrogen Economy

Green hydrogen will be an essential element in decarbonizing the global economy. By connecting excess renewable energy to water electrolyzers, utilities can produce emission-free hydrogen that can be used to heat homes, power industries, and fuel mobility.

Hydrogen is the most abundant element in the universe, but pure hydrogen is scarce here on Earth. However, utilities can make it by splitting water into its two components using an electrolyzer— essentially a fuel cell running in reverse. The catalyst-coated Nafion™ ion-exchange membrane helps separate hydrogen and oxygen from water through electrolysis, and when the process is powered by renewable energy, it is completely emissions-free.

Switching the world’s energy economy over to hydrogen seems like a daunting task, but, fortunately, the gas grid we need is already in place. Once sufficient quantities of green hydrogen are available, utilities can substitute it for natural gas and send it anywhere the grid reaches—from homes to businesses. As hydrogen use grows, the grid will expand with it, extending out to more buildings and creating a network of hydrogen filling stations for FCEVs.

Some energy-intensive industries like steel or ammonia production can gain a double benefit by switching to green hydrogen. Not only can it be burned cleanly for heat or power, it can also serve as a feedstock for crucial industrial processes.

Hydrogen can also replace fossil fuels in industrial processes, like steel and ammonia production, which could greatly reduce the 20% of global greenhouse gas emissions created by industry, according to Bloomberg Green. Green hydrogen is an essential part of the nascent renewable energy ecosystem that will give our world its best shot at meeting net zero emissions goals by 2050, according to BloombergNEF’s New Energy Outlook.

Firmly focused on innovations that result in more sustainable solutions, Chemours is responding to both customer demands and the reality of climate change. The company is developing environmentally responsible products to improve lives. As the world continues to demand and expect modern conveniences that make life better and are good for people and the planet, chemistry will become more important than ever.

“When we say we want a green alternative for clean energy, one that doesn’t use fossil fuels or produce CO2 emissions, one of the best options we have is green hydrogen.”

Tekie Zeru, Vice President of Technology, Advanced Performance Materials

Learn more about how Chemours Nafion™ membrane technology reduces wasted energy and facilitates clean hydrogen production.