Jun 27, 2023

How Can Technology Drive Sustainability in the Supply Chain?

The Challenge

The global supply chain has faced increased scrutiny in recent years amid growing concern around climate change, human rights and corporate responsibility. Supply chain sustainability is motivated by factors including consumer demand, investor pressure, resource security, human rights and legislative agendas.

According to a 2022 global EY study, eight in 10 supply chain executives are increasing their efforts toward sustainable operations, but the complexity and lack of visibility of global supply chains and the need for resilience pose challenges.

Gunther Rothermel, SAP’s Co-GM and Chief Product Officer for Sustainability, explains that businesses are facing tightened legislation on sustainability in many markets around the globe.

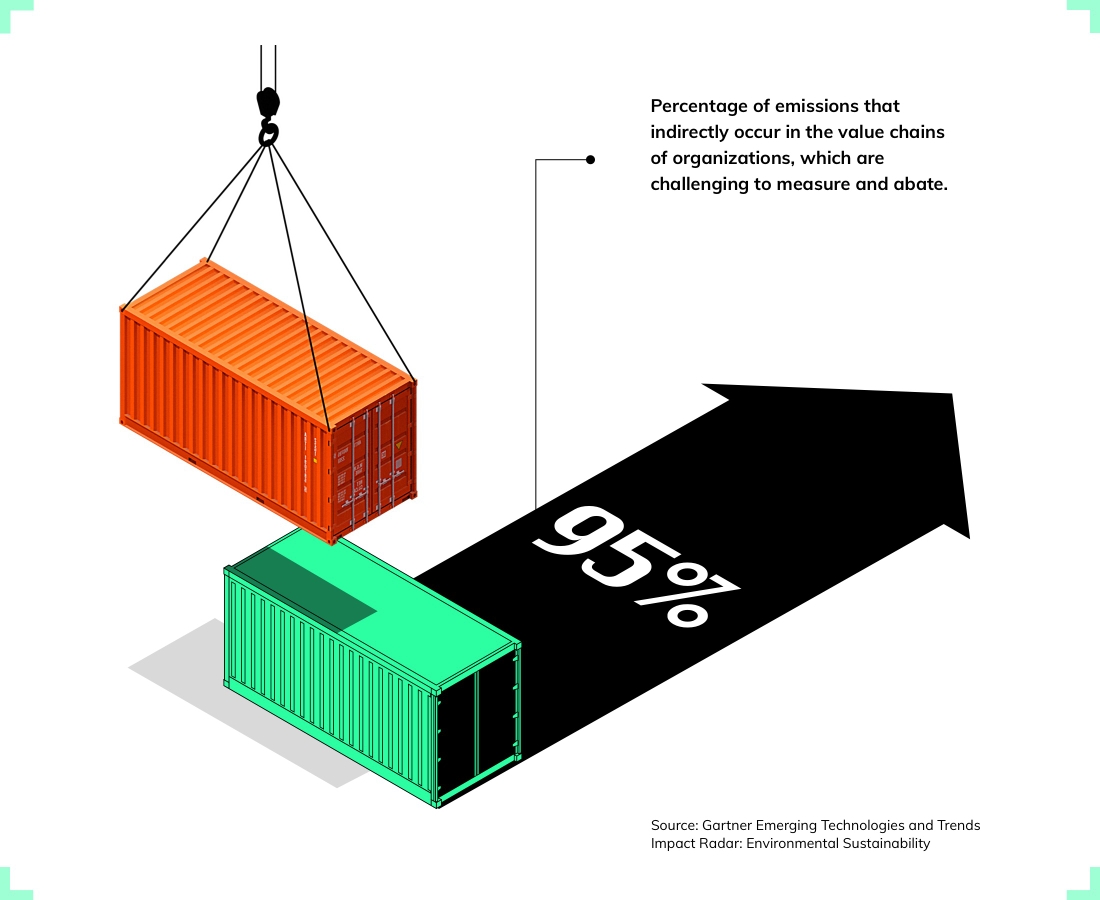

“In the past, procurement might have looked at a technical specification and negotiated a price. In the future, sustainability in a supply chain becomes possible for businesses that are equipped to record, report and act on scopes 1–3 emissions data,” says Rothermel. “Companies can rise beyond the compliance challenge with a reliable data foundation enabled by the exchange of data along supply chains.”

The Impact

Companies can increase their climate impact and enable emission reductions in hard-to-abate sectors with minimal cost to the consumer by working with suppliers toward establishing a net-zero supply chain.

By incorporating ESG analytics across product design and development, sourcing, manufacturing processes and life cycle planning and reporting, technology is supporting sustainability-led transformation by helping stakeholders make more responsible decisions underpinned by data.

According to the World Economic Forum, circularity through the reuse and recycling of products, improved efficiency and the use of renewable energy could reduce almost 40% of emissions in supply chains, with just a minor impact on product pricing.

Cloud technology products are now unifying data intelligence and providing organizations with the overall visibility needed to both improve sustainability reporting and track the insights needed to make decisions for long-term business transformation, explains Musidora Jorgensen, Microsoft Chief Sustainability Officer, U.K.

“The ability to unify data to provide the insights needed to reduce the overall impact across carbon emissions, water and waste is where organizations are struggling at the moment, primarily because it’s so complex to do,” says Jorgensen.

Sheri Hinish, EY’s Principal, Americas and Global Sustainability Innovation and Ecosystem Leader, says that AI plays a crucial role in enabling this effort.

“AI is a partner that can help you identify trends and patterns using large amounts of data, and that gives you insights that you otherwise wouldn’t have readily available,” she says. This includes how organizations can make operations more efficient or use machine learning algorithms to model carbon-responsible logistics networks and circular thinking, she explains.

“Using AI in demand forecasting based on responsible inventory management uses many decision points to model more sustainable decision orchestration end-to-end,” says Hinish. ”When coupled with technologies like digital twinning, these simulations can help organizations use existing data and run scenario models with a net-zero lens that can uncover opportunities around eco-efficiency, resource use and other ESG-related metrics.”

It can also promote operational efficiency throughout the supply chain by cutting down on energy use, which is critical to lowering carbon emissions.

“With AI technology, companies can quickly evaluate what-if scenarios, such as alternative supplier sourcing, alternative route planning or prioritizing different KPIs—for example, prioritizing carbon footprint over cost or time,” says Rishi Vaish, CTO and VP, IBM Sustainability Software. “In this way, AI can help businesses respond to disruptions with agility, making them more resilient and more carbon-efficient.”

Bringing operational data like this into how companies plan and operate their key processes is the next big step in corporate sustainability, says Sean Jones, Microsoft Chief Sustainability Officer, Germany.

“When thinking about planning for production, supply chains and transportation, staff need operational sustainability data to determine the optimal production plan based on CO2 output vs. an alternative production plan that may result in faster delivery,” says Jones. “Managers require sustainability data to make informed decisions on the trade-offs on a daily basis.”

There are other trade-offs to be assessed when making decisions about which technology supports an organization’s goals. For example, blockchain technology has attracted headlines as an immutable record ledger, meaning that organizations can trace each step in the supply chain to understand provenance, carbon footprint changes resulting from transformation and other attributes. This allows organizations to demonstrate, for example, proof of ethical and sustainable sourcing in their supply chains.

But blockchain has faced considerable criticism, primarily due to its implementation of a consensus mechanism that is energy-intensive. There are other variants of these consensus algorithms to pick from, some of which are superior to others in energy efficiency.

Blockchain technology is still in its early stages, which is why businesses need to run feasibility studies to understand its impact and how to strike a balance between increasing security and environmental sustainability. Lessons can be learned from industries adopting technology to help inform value-led sustainability decisions on product development, regulation, customer engagement and supplier management.

“When you think about what it means to realize a net-zero and equitable world, it really comes down to trust and the feeling of transparency, and how to document proof of performance in the supply chain,” says Hinish.

One example of how this technology is being implemented is in the fisheries industry. Kvarøy Arctic, a pioneer in sustainable fish farming based in Norway, is enabling corporate buyers and restaurants to scan a QR code that provides a provenance history for Arctic salmon and the feed they are raised on.

“Buyers are able to download images and videos of the farms and see for themselves the conditions and animal welfare standards that Kvarøy Arctic upholds. The company also plans to introduce a consumer app to provide insight into the quality and sustainability of their seafood in the future,” says Rishi Vaish, CTO and VP, IBM Sustainability Software.

Without technology, managing multiple stakeholders in the supply chain is hard to track, and sustainability impact is nearly impossible to measure.

The Takeaway

There are three ways businesses can accelerate the value and sustainable impact of their supply chains, explains Hinish.

“Start by defining the impact you want to achieve and how to make it operational using technology. Then place human beings, or copilots, at the center of transformational sustainability, where you rethink how work gets done and how to make more responsible decisions. The third element is to assess how to use and finance emerging technology that is creating access to transition to a net-zero and equitable world.”

“Ultimately, supply chain emissions are a combination of what we choose to build and how we choose to build it,” says Donna Warton, Microsoft Corporate Vice President, Supply Chain and Sustainability. “It’s critical to leverage the right standards, such as life cycle assessment, that can harmonize product, material, supplier and geographic emissions into a joint impact roadmap. Using our digital carbon platform, we are able to map process changes at individual suppliers to specific products, which we publish as part of all-up product carbon footprints in our Device EcoProfiles.”

Hinish warns that one major pitfall is that supply chains frequently equate sustainability only with the goal of lowering emissions, at the expense of other important sustainability considerations.

“This is referred to as ‘carbon tunnel vision,’ an emerging term that calls for organizations to adopt a more comprehensive approach to sustainability and defining impact,” she says. This could include environmental factors such as water use, land use, biodiversity, air and water pollution and waste production, and social considerations like labor rights, access to a fair living wage and the community impact of the business.

Jorgensen emphasizes that the goal is to achieve sustainable outcomes faster by leveraging emerging technologies, contributing to wider business transformation. “The ability to unify data across the complete value chain of an organization can provide the overall visibility an organization needs to both improve sustainability reporting and track insights needed to make decisions for long-term business transformation.”

We are in the midst of a climate emergency, a business model emergency and a social emergency. When businesses are reconciling the return on investment of making this transition, we’re talking about clean water, breathable air—something that we have to do for survival, for the natural environment and also for our species.

Sheri HinishPrincipal, EY Americas and EY Global Sustainability Innovation and Ecosystem Leader

The C-suite needs to find novel ways of enabling that information flow. It’s a new level of trust within and between organizations, but it’s also a new way to think about the emissions that you create as a company based on the emissions from your value chain.

Steve VarleyEY Global Vice Chair for Sustainability